Page 319 - IJB-9-1

P. 319

International Journal of Bioprinting Sterilization effect on 3D printed inks

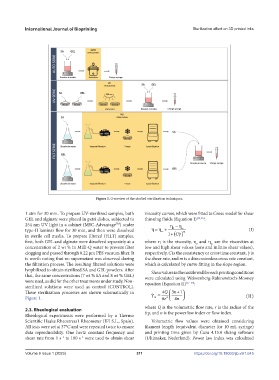

Figure 1. Overview of the studied sterilization techniques.

1 atm for 30 min. To prepare UV-sterilized samples, both viscosity curves, which were fitted to Cross model for shear

GEL and alginate were placed in petri dishes, subjected to thinning fluids (Equation I) [35,36] :

254 nm UV light in a cabinet (MSC-Advantage ) under η − η

TM

0

type-II laminar flow for 30 min, and then were dissolved η η= ∞ + +( ) ∞ m (I)

.

in sterile cell media. To prepare filtered (FILT) samples, 1 Cγ

first, both GEL and alginate were dissolved separately at a where η is the viscosity, η and η are the viscosities at

∞

0

concentration of 2 wt % in Milli-Q water to prevent filter low and high shear values (zero and infinite shear values),

⋅

clogging and passed through 0.22 µm PES vacuum filter. It respectively, C is the consistency or cross time constant, γ is

is worth noting that no supernatant was observed during the shear rate, and m is a dimensionless cross rate constant,

the filtration process. The resulting filtered solutions were which is calculated by curve fitting in the slope region.

lyophilized to obtain sterilized SA and GEL powders. After Shear values in the nozzle wall for each printing conditions

that, the same concentrations (7 wt % SA and 8 wt % GEL) were calculated using Weissenberg-Rabinowitsch-Mooney

were used, as did for the other treatments under study. Non- equation (Equation II) [37–39] :

sterilized solutions were used as control (CONTROL).

.

These sterilization processes are shown schematically in γ = 4 Q 3 n + 1

Figure 1. w π r 4 n (II)

3

where Q is the volumetric flow rate, r is the radius of the

2.3. Rheological evaluation tip, and n is the power law index or flow index.

Rheological experiments were performed by a Thermo

Scientific Haake Rheostress1 Rheometer (IFI S.L., Spain). Volumetric flow values were obtained considering

All tests were set at 37°C and were repeated twice to ensure filament length (equivalent diameter for 10 mL syringe)

data reproducibility. One hertz constant frequency and and printing time given by Cura 4.13.0 slicing software

shear rate from 1 s to 100 s were used to obtain shear (Ultimaker, Nederland). Power law index was calculated

−1

−1

Volume 9 Issue 1 (2023) 311 https://doi.org/10.18063/ijb.v9i1.645