Page 296 - IJB-9-2

P. 296

International Journal of Bioprinting Methodology of hydrogel printability

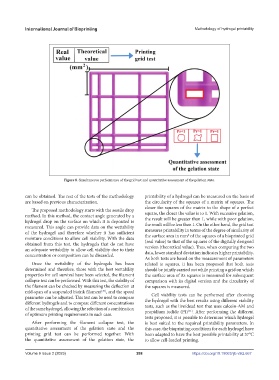

Figure 8. Simultaneous performance of the grid test and quantitative assessment of the gelation state.

can be obtained. The rest of the tests of the methodology printability of a hydrogel can be measured on the basis of

are based on previous characterization. the circularity of the squares of a matrix of squares. The

closer the squares of the matrix to the shape of a perfect

The proposed methodology starts with the sessile drop

method. In this method, the contact angle generated by a square, the closer the value is to 1. With excessive gelation,

the result will be greater than 1, while with poor gelation,

hydrogel drop on the surface on which it is deposited is the result will be less than 1. On the other hand, the grid test

measured. This angle can provide data on the wettability measures printability in terms of the degree of similarity of

of the hydrogel and therefore whether it has sufficient the surface area in mm of the squares of a bioprinted grid

2

moisture conditions to allow cell viability. With the data (real value) to that of the squares of the digitally designed

obtained from this test, the hydrogels that do not have version (theoretical value). Thus, when comparing the two

an adequate wettability to allow cell viability due to their data, lower standard deviation indicates higher printability.

concentration or composition can be discarded.

As both tests are based on the measurement of parameters

Once the wettability of the hydrogels has been related to squares, it has been proposed that both tests

determined and therefore, those with the best wettability should be jointly carried out while printing a grid on which

properties for cell survival have been selected, the filament the surface area of its squares is measured for subsequent

collapse test can be performed. With this test, the stability of comparison with its digital version and the circularity of

the filament can be checked by measuring the deflection at the squares is measured.

mid-span of a suspended bioink filament , and the speed

[30]

parameter can be adjusted. This test can be used to compare Cell viability tests can be performed after choosing

different hydrogels and to compare different concentrations the hydrogel with the best results using different viability

of the same hydrogel, allowing the selection of a combination tests, such as the live/dead test that uses calcein-AM and

[31]

of optimum printing requirements in each case. propidium iodide (PI) . After performing the different

tests proposed, it is possible to determine which hydrogel

After performing the filament collapse test, the is best suited to the required printability parameters. In

quantitative assessment of the gelation state and the this case, the bioprinting conditions for each hydrogel have

printing grid test can be performed together. With been adapted to have the best possible printability at 37°C

the quantitative assessment of the gelation state, the to allow cell-loaded printing.

Volume 9 Issue 2 (2023) 288 https://doi.org/10.18063/ijb.v9i2.667