Page 390 - IJB-9-2

P. 390

International Journal of Bioprinting In situ 3D bioprinter for skin wound healing

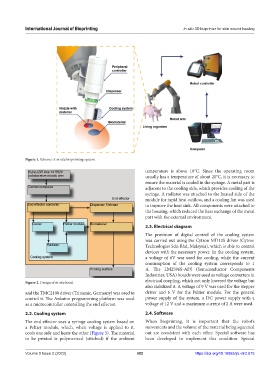

Figure 1. Scheme of in situ bioprinting system.

temperature is above 10°C. Since the operating room

usually has a temperature of about 20°C, it is necessary to

ensure the material is cooled in the syringe. A metal part is

adjacent to the cooling side, which provides cooling of the

syringe. A radiator was attached to the heated side of the

module for rapid heat outflow, and a cooling fan was used

to improve the heat sink. All components were attached to

the housing, which reduced the heat exchange of the metal

part with the external environment.

2.3. Electrical diagram

The provision of digital control of the cooling system

was carried out using the Cytron MD13S driver (Cytron

Technologies Sdn Bhd, Malaysia), which is able to control

devices with the necessary power. In the cooling system,

a voltage of 6V was used for cooling, while the current

consumption of the cooling system corresponds to 1

A. The LM2596S-ADJ (Semiconductor Components

Industries, USA) boards were used as voltage converters in

Figure 2. Design of in situ head. electrical coupling, which not only lowered the voltage but

also stabilized it. A voltage of 9 V was used for the stepper

and the TMC2100 driver (Trinamic, Germany) was used to driver and 6 V for the Peltier module. For the general

control it. The Arduino programming platform was used power supply of the system, a DC power supply with a

as a microcontroller controlling the end effector. voltage of 12 V and a maximum current of 2 A were used.

2.2. Cooling system 2.4. Software

The end effector uses a syringe cooling system based on When bioprinting, it is important that the robot’s

a Peltier module, which, when voltage is applied to it, movements and the volume of the material being squeezed

cools one side and heats the other (Figure 3). The material out are consistent with each other. Special software has

to be printed is polymerized (stitched) if the ambient been developed to implement this condition. Special

Volume 9 Issue 2 (2023) 382 https://doi.org/10.18063/ijb.v9i2.675