Page 231 - IJB-9-3

P. 231

International Journal of Bioprinting Biomaterials for vascularized and innervated tissue regeneration

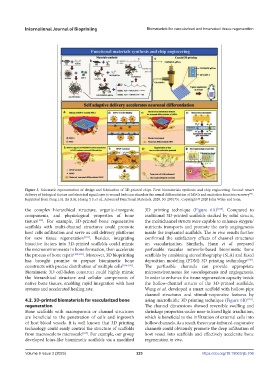

Figure 5. Schematic representation of design and fabrication of 3D-printed chips. First: biomaterials synthesis and chip engineering. Second: smart

delivery of biological factors and electrical signal cues to wound beds can stimulate the neural differentiation of MSCs and excitation function recovery .

[92]

Reprinted from Peng L H, Xu X H, Huang Y F, et al., Advanced Functional Materials, 2020, 30: 2001751. Copyright © 2020 John Wiley and Sons.

the complex hierarchical structure, organic–inorganic 3D printing technique (Figure 6A) [108] . Compared to

components, and physiological properties of bone traditional 3D-printed scaffolds stacked by solid structs,

tissues [100] . For example, 3D-printed bone regenerative the multichannel structs were capable to enhance oxygen/

scaffolds with multi-channel structures could promote nutrients transports and promote the early angiogenesis

host cells infiltration and serve as cell delivery platforms inside the implanted scaffolds. The in vivo results further

for new tissue regeneration [101] . Besides, integrating confirmed the satisfactory effects of channel structures

bioactive factors into 3D-printed scaffolds could mimic on vascularization. Similarly, Hann et al. prepared

the microenvironments in bone formation, then accelerate perfusable vascular networks-based biomimetic bone

the process of bone repair [102,103] . Moreover, 3D bioprinting scaffolds by combining stereolithography (SLA) and fused

has brought promise to prepare biomimetic bone deposition modeling (FDM) 3D printing technology [109] .

constructs with precise distribution of multiple cells [104-106] . The perfusable channels can provide appropriate

Biomimetic 3D cell-laden construct could highly mimic microenvironments for vasculogenesis and angiogenesis.

the hierarchical structure and cellular components of In order to enhance the tissue regeneration capacity inside

native bone tissues, enabling rapid integration with host the hollow-channel structs of the 3D-printed scaffolds,

systems and accelerated healing rate. Wang et al. developed a smart scaffold with hollow-pipe

channel structures and stimuli-responsive features by

4.2. 3D-printed biomaterials for vascularized bone using microfluidic 3D printing technique (Figure 6B) [110] .

regeneration The channel dimensions showed reversible swelling and

Bone scaffolds with macroporous or channel structures shrinkage properties under near-infrared light irradiation,

are beneficial to the penetration of cells and ingrowth which is beneficial to the infiltration of external cells into

of host blood vessels. It is well known that 3D printing hollow channels. As a result, these near-infrared-responsive

technology could easily control the structure of scaffolds channels could obviously promote the deep infiltration of

from macroscale to microscale [107] . For example, our group host vessel into scaffolds and effectively accelerate bone

developed lotus-like biomimetic scaffolds via a modified regeneration in vivo.

Volume 9 Issue 3 (2023) 223 https://doi.org/10.18063/ijb.706