Page 316 - IJB-9-4

P. 316

International Journal of Bioprinting Biomechanical properties of 3D printable material

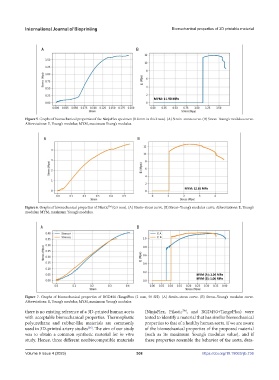

Figure 5. Graphs of biomechanical properties of the NinjaFlex specimen (0.8 mm in thickness). (A) Strain–stress curve. (B) Stress–Young’s modulus curve.

Abbreviations: E, Young’s modulus; MYM, maximum Young’s modulus.

Figure 6. Graphs of biomechanical properties of Filastic (0.5 mm). (A) Strain–stress curve. (B) Stress–Young’s modulus curve. Abbreviations: E, Young’s

TM

modulus; MYM, maximum Young’s modulus.

Figure 7. Graphs of biomechanical properties of RGD450+TangoPlus (2 mm, 50 SH). (A) Strain–stress curve. (B) Stress–Young’s modulus curve.

Abbreviations: E, Young’s modulus; MYM, maximum Young’s modulus.

there is no existing reference of a 3D-printed human aorta (NinjaFlex, Filastic , and RGD450+TangoPlus) were

TM

with acceptable biomechanical properties. Thermoplastic tested to identify a material that has similar biomechanical

polyurethane and rubber-like materials are commonly properties to that of a healthy human aorta. If we are aware

used in 3D-printed artery studies . The aim of our study of the biomechanical properties of the proposed material

[26]

was to obtain a common synthetic material for in vitro (such as its maximum Young’s modulus value), and if

study. Hence, three different nonbiocompatible materials these properties resemble the behavior of the aorta, data-

Volume 9 Issue 4 (2023) 308 https://doi.org/10.18063/ijb.736