Page 367 - IJB-9-5

P. 367

International Journal of Bioprinting Multifunctional hydrogel surgical training model

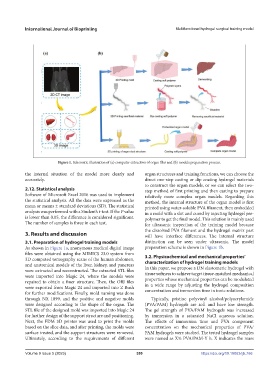

Figure 1. Schematic illustration of (a) computer extraction of organ files and (b) models preparation process.

the internal situation of the model more clearly and organ structures and training functions, we can choose the

accurately. direct one-step casting or dip coating hydrogel materials

to construct the organ models, or we can select the two-

2.12. Statistical analysis step method of first printing and then casting to prepare

Software of Microsoft Excel 2016 was used to implement relatively more complex organ models. Regarding this

the statistical analysis. All the data were expressed as the method, the internal structure of the organ model is first

mean or means ± standard deviations (SD). The statistical printed using water-soluble PVA filament, then embedded

analysis was performed with a Student’s t-test. If the P value in a mold with a slot and cured by injecting hydrogel pre-

is lower than 0.05, the difference is considered significant. polymer to get the final model. This solution is mainly used

The number of samples is three in each test. for ultrasonic inspection of the training model because

the dissolved PVA filament and the hydrogel matrix part

3. Results and discussion will have interface differences. The internal structure

3.1. Preparation of hydrogel training models distinction can be seen under ultrasonic. The model

As shown in Figure 1a, anonymous medical digital image preparation scheme is shown in Figure 1b.

files were obtained using the MIMICS 23.0 system from

3D computed tomography scans of the human abdomen, 3.2. Physicochemical and mechanical properties’

and anatomical models of the liver, kidney, and pancreas characterization of hydrogel training models

were extracted and reconstructed. The extracted STL files In this paper, we propose a DN elastomeric hydrogel with

were imported into Magic 24, where the models were tissue softness to achieve target tissue-matched mechanical

repaired to obtain a finer structure. Then, the OBJ files properties whose mechanical properties can be modulated

were exported from Magic 24 and imported into Z Bush in a wide range by adjusting the hydrogel composition

for further modifications. Finally, mold naming was done concentration and immersion time in ionic solutions.

through NX 1899, and the positive and negative molds Typically, pristine polyvinyl alcohol/polyacrylamide

were designed according to the shape of the organ. The (PVA/PAM) hydrogels are soft and have low strength.

STL file of the designed mold was imported into Magic 24 The gel strength of PVA/PAM hydrogels was increased

for further design of the support structure and positioning. by immersion in a saturated NaCl aqueous solution.

Next, the FDM 3D printer was used to print the molds The effects of immersion time and PVA component

based on the slice data, and after printing, the molds were concentration on the mechanical properties of PVA/

surface treated, and the support structures were removed. PAM hydrogels were studied. The tested hydrogel samples

Ultimately, according to the requirements of different were named as X% PVA/PAM-Y h. X indicates the mass

Volume 9 Issue 5 (2023) 359 https://doi.org/10.18063/ijb.766