Page 379 - IJB-9-5

P. 379

International Journal of Bioprinting Vascularized bone regeneration

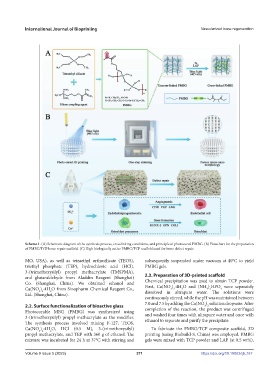

Scheme 1. (A) Schematic diagram of the synthesis process, crosslinking conditions, and principle of photocured PMBG. (B) Flowchart for the preparation

of PMBG/TCP bone repair scaffold. (C) High biologically active PMBG/TCP scaffold used for bone defect repair.

MO, USA), as well as tetraethyl orthosilicate (TEOS), subsequently suspended under vacuum at 40°C to yield

triethyl phosphate (TEP), hydrochloric acid (HCl), PMBG gels.

3-(trimethoxysilyl) propyl methacrylate (TMSPMA),

and glutaraldehyde from Aladdin Reagent (Shanghai) 2.3. Preparation of 3D-printed scaffold

Co. (Shanghai, China). We obtained ethanol and Chemical precipitation was used to obtain TCP powder.

Ca(NO ) ·4H O from Sinopharm Chemical Reagent Co., First, Ca(NO ) ·4H O and (NH ) HPO were separately

4 2

4

2

3 2

2

3 2

Ltd. (Shanghai, China). dissolved in ultrapure water. The solutions were

continuously stirred, while the pH was maintained between

7.0 and 7.5 by adding the Ca(NO ) solution dropwise. After

2.2. Surface functionalization of bioactive glass completion of the reaction, the product was centrifuged

3 2

Photocurable MBG (PMBG) was synthesized using and washed four times with ultrapure water and once with

3-(trimethoxysilyl) propyl methacrylate as the modifier. ethanol to separate and purify the precipitate.

The synthesis process involved mixing F-127, TEOS,

Ca(NO ) ·4H O, HCl (0.5 M), 3-(trimethoxysilyl) To fabricate the PMBG/TCP composite scaffold, 3D

2

3 2

propyl methacrylate, and TEP with 360 g of ethanol. The printing (using Biobuild-S, China) was employed. PMBG

mixture was incubated for 24 h at 37°C with stirring and gels were mixed with TCP powder and LAP (at 0.5 wt%),

Volume 9 Issue 5 (2023) 371 https://doi.org/10.18063/ijb.767