Page 210 - IJB-9-6

P. 210

International Journal of Bioprinting Multi-Cellular tissues/organoids manufacturing strategies

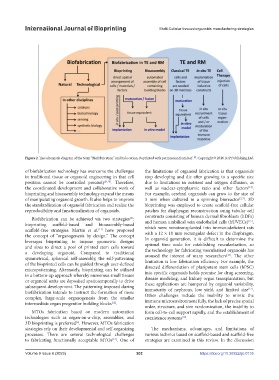

Figure 2. The schematic diagram of the term “Biofabrication” and its location. Reprinted with permission from Ref. . Copyright © 2016 IOP Publishing Ltd.

[8]

of biofabrication technology has overcome the challenges the limitations of organoid fabrication is that organoids

in traditional tissue or organoid engineering in that cell stop developing and die after growing to a specific size

position cannot be controlled precisely [9,10] . Therefore, due to limitations in nutrient and oxygen diffusion, as

the coordinated development and collaborative work of well as nuclear-cytoplasmic ratio and other factors .

[14]

bioprinting and bioassembly technology expand the means For example, cerebral organoids can grow to the size of

of manipulating organoid growth. It also helps to improve 3 mm when cultured in a spinning bioreactor [2,3] . 3D

the standardization of organoid fabrication and realize the bioprinting was employed to create scaffold-free cellular

reproducibility and functionalization of organoids. patches for diaphragm reconstruction using tabular cell

constructs consisting of human dermal fibroblasts (hDFs)

Biofabrication can be achieved via two strategies :

[8]

[15]

bioprinting scaffold-based and bioassembly-based and human umbilical vein endothelial cells (hUVECs) ,

scaffold-free strategies. Martin et al. have proposed which were xenotransplanted into immunodeficient rats

[11]

the concept of “organogenesis by design.” The concept with a 12 × 10 mm rectangular defect in the diaphragm.

leverages bioprinting to impose geometric designs In organoid generation, it is difficult to determine the

and sizes to direct a pool of printed stem cells toward optimal time node for establishing vascularization, so

a developing organoid. Compared to traditional the technology for fabricating vascularized organoids has

[16]

symmetrical, spherical self-assembly, the self-patterning aroused the interest of many researchers . The other

of the bioprinted cells can be guided through user-defined limitation is low fabrication efficiency. For example, the

micropatterning. Alternately, bioprinting can be utilized directed differentiation of pluripotent stem cells (hPSC)

in a bottom-up approach whereby numerous small tissues into specific organoids holds promise for drug screening,

or organoid units are deposited spatiotemporally to drive disease modeling, and kidney organ transplantation, but

subsequent development. The patterning imposed during these applications are hampered by organoid variability,

[17]

biofabrication intends to instruct the formation of more immaturity of nephrons, low yield, and limited size .

complex, large-scale organogenesis from the smaller Other challenges include the inability to mimic the

[12]

intermediate organ progenitor building blocks . immune microenvironment fully, the lack of precise spatial

order, structure, and size randomization, the inability to

MTOs fabrication based on modern automation form cell-to-cell support rapidly, and the establishment of

technologies such as organ-on-a-chip, assemblies, and coexistence systems .

[18]

3D bioprinting is preferred . However, MTOs fabrication

[6]

strategies rely on their developmental and self-organizing The mechanisms, advantages, and limitations of

processes. There are several technological challenges various technics based on scaffold-based and scaffold-free

to fabricating functionally acceptable MTOs . One of strategies are examined in this review. In the discussion

[13]

Volume 9 Issue 6 (2023) 202 https://doi.org/10.36922/ijb.0135