Page 285 - IJB-9-6

P. 285

International Journal of Bioprinting Progress in bioprinted ear reconstruction

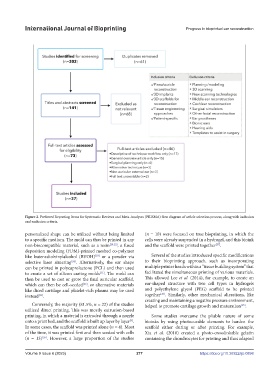

Figure 2. Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) flow diagram of article selection process, along with inclusion

and exclusion criteria.

personalized shape can be utilized without being limited (n = 10) were focused on true bioprinting, in which the

to a specific medium. The mold can thus be printed in any cells were already suspended in a hydrogel, and this bioink

[27]

non-biocompatible material, such as a resin [20,22] , a fused and the scaffold were printed together .

deposition modeling (FDM)-printed meshed co-polymer

[23]

like butenediolvinylalcohol (BVOH) or a powder via Several of the studies introduced specific modifications

[24]

selective laser sintering . Alternatively, the ear shape to their bioprinting approach, such as incorporating

can be printed in polycaprolactone (PCL) and then used multiple printer heads within a “tissue building system” that

[11]

to create a set of silicon casting molds . The mold can facilitated the simultaneous printing of various materials.

then be used to cast or grow the final auricular scaffold, This allowed Lee et al. (2014), for example, to create an

[25]

which can then be cell-seeded , or alternative materials ear-shaped structure with two cell types in hydrogels

like diced cartilage and platelet-rich plasma may be used and polyethylene glycol (PEG) scaffold to be printed

[26]

[24]

instead . together . Similarly, other mechanical alterations, like

creating and maintaining a negative pressure environment,

Conversely, the majority (81.5%, n = 22) of the studies helped to promote cartilage growth and maturation .

[25]

utilized direct printing. This was mostly extrusion-based

printing, in which a material is extruded through a nozzle Some studies overcame the pliable nature of some

onto a print bed, and the scaffold is built up layer by layer . bioinks by using photocurable elements to harden the

[9]

In some cases, the scaffold was printed alone (n = 4). Most scaffold either during or after printing. For example,

of the time, it was printed first and then seeded with cells Xia et al. (2018) created a photo-crosslinkable gelatin

(n = 13) . However, a large proportion of the studies containing the chondrocytes for printing and thus adapted

[26]

Volume 9 Issue 6 (2023) 277 https://doi.org/10.36922/ijb.0898