Page 74 - MSAM-4-1

P. 74

Materials Science in Additive Manufacturing In situ electromagnetic field manipulation during LMD

A B

C D

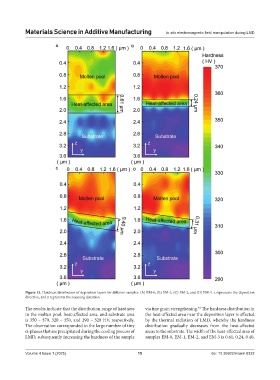

Figure 13. Hardness distribution of deposition layers for different samples: (A) EM-0; (B) EM-1; (C) EM-2; and (D) EM-3. z represents the deposition

direction, and y represents the scanning direction

The results indicate that the distribution range of hardness via fine grain strengthening. The hardness distribution in

40

in the molten pool, heat-affected area, and substrate area the heat-affected area near the deposition layer is affected

is 350 – 370, 320 – 350, and 290 – 320 HV, respectively. by the thermal radiation of LMD, whereby the hardness

The observation corresponded to the large number of tiny distribution gradually decreases from the heat-affected

α-phases that are precipitated during the cooling process of areas to the substrate. The width of the heat-affected area of

LMD, subsequently increasing the hardness of the sample samples EM-0, EM-1, EM-2, and EM-3 is 0.61, 0.24, 0.40,

Volume 4 Issue 1 (2025) 15 doi: 10.36922/msam.8332