Page 111 - EER-2-3

P. 111

Explora: Environment

and Resource Enzymatic degradation

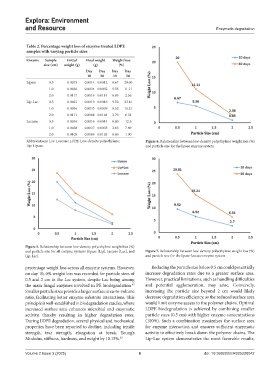

Table 2. Percentage weight loss of enzyme‑treated LDPE

samples with varying particle sizes

Enzyme Sample Initial Final weight Weight loss

size (cm) weight (g) (g) (%)

Day Day Day Day

10 30 10 30

Lipase 0.5 0.0015 0.0014 0.0012 6.67 20.00

1.0 0.0036 0.0034 0.0032 5.56 11.11

2.0 0.0117 0.0116 0.0114 0.85 2.56

Lip-Lac 0.5 0.0021 0.0019 0.0016 9.52 23.81

1.0 0.0046 0.0043 0.0039 6.52 15.21

2.0 0.0111 0.0108 0.0104 2.70 6.31

Laccase 0.5 0.0016 0.0016 0.0014 0.00 12.5

1.0 0.0038 0.0037 0.0035 2.63 7.89

2.0 0.0105 0.0105 0.0103 0.00 1.90

Abbreviations: Lac: Laccase; LDPE: Low-density polyethylene; Figure 6. Relationship between low-density polyethylene weight loss (%)

Lip: Lipase. and particle size for the lipase enzyme system

Figure 5. Relationship between low-density polyethylene weight loss (%)

and particle size for all enzyme systems (lipase [Lip], laccase [Lac], and Figure 7. Relationship between low-density polyethylene weight loss (%)

Lip-Lac). and particle size for the lipase-laccase enzyme system

percentage weight loss across all enzyme systems. However, Reducing the particle size below 0.5 cm could potentially

on day 10, 0% weight loss was recorded for particle sizes of increase degradation rates due to a greater surface area.

0.5 and 2 cm in the Lac system, despite Lac being among However, practical limitations, such as handling difficulties

the main fungal enzymes involved in PE biodegradation. and potential agglomeration, may arise. Conversely,

62

Smaller particle sizes provide a larger surface area-to-volume increasing the particle size beyond 2 cm would likely

ratio, facilitating better enzyme-substrate interactions. This decrease degradation efficiency, as the reduced surface area

principle is well-established in biodegradation studies, where would limit enzyme access to the polymer chains. Optimal

increased surface area enhances microbial and enzymatic LDPE biodegradation is achieved by combining smaller

activity, thereby resulting in higher degradation rates. particle sizes (0.5 cm) with higher enzyme concentrations

During LDPE degradation, several physical and mechanical (100%). Such a combination maximizes the surface area

properties have been reported to decline, including tensile for enzyme interaction and ensures sufficient enzymatic

strength, tear strength, elongation at break, Young’s activity to effectively break down the polymer chains. The

Modulus, stiffness, hardness, and weight by 10.15%. 63 Lip-Lac system demonstrates the most favorable results,

Volume 2 Issue 3 (2025) 6 doi: 10.36922/EER025220042