Page 112 - EER-2-3

P. 112

Explora: Environment

and Resource Enzymatic degradation

consistently achieving higher weight loss percentages confirms the material’s resistance to degradation in the

across all particle sizes. This synergistic effect enhances absence of enzymatic activity. These control images are

LDPE breakdown, making it the preferred enzymatic crucial for comparing the extent of degradation observed

treatment for effective biodegradation. in the enzyme-treated LDPE samples. It was previously

established that the PE surface changes after 30 days of

3.3. Microscopy imaging of enzyme-treated LDPE incubation with enzymes. 65

samples

Figure 9, representing the control LDPE film, exhibits

3.3.1. Effect of different enzyme concentrations a smooth and uniform surface, indicating no degradation.

Rough surfaces and pore structures are observed in all In contrast, Figure 10, depicting the LDPE film treated

LDPE samples incubated with enzymes, and the features with Lip, displays noticeable surface alterations, such as

are more significant in samples incubated in 100% enzyme pits, grooves, and rough textures, similar to a previous

66

67

concentration, likely due to enzymatic activity on the observation using Bacillus spp. YP1. Das and Kumar

64

LDPE samples. Figures 9-12 display the SEM images of inferred that Lip treatment initiates the LDPE degradation

LDPE films (1 × 1 cm). Each image illustrates the surface process, leading to polymer surface breakdown. Figure 10

morphology of LDPE under different treatment conditions: presents the SEM images of LDPE films treated with Lip at

untreated/control (Figure 9), Lip-treated (Figure 10), Lip- different magnifications. The images reveal the formation

Lac-treated (Figure 11), and Lac-treated (Figure 12). The of surface irregularities, including pits and cracks,

68,69

consistent sample size and imaging technique across these indicating the onset of enzymatic degradation. Higher

figures facilitate a comparative analysis of the effects of magnifications highlight more detailed degradation

features, such as micro-cracks and increased surface

enzymatic treatments on LDPE surface degradation. The roughness. The presence of white and dark areas in the

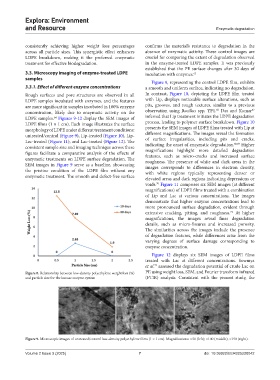

SEM images in Figure 9 serve as a baseline, showcasing images corresponds to differences in electron density,

the pristine condition of the LDPE film without any with white regions typically representing denser or

enzymatic treatment. The smooth and defect-free surface elevated areas and dark regions indicating depressions or

voids. Figure 11 comprises six SEM images (at different

70

magnifications) of LDPE films treated with a combination

of Lip and Lac at various concentrations. The images

demonstrate that higher enzyme concentrations lead to

more pronounced surface degradation, evident through

71

extensive cracking, pitting, and roughness. At higher

magnifications, the images reveal finer degradation

details, such as micro-fissures and increased porosity.

The similarities across the images include the presence

of degradation features, while differences arise from the

varying degrees of surface damage corresponding to

enzyme concentration.

Figure 12 displays six SEM images of LDPE films

treated with Lac at different concentrations. Sowmya

et al. assessed the degradation potential of crude Lac on

72

Figure 8. Relationship between low-density polyethylene weight loss (%) PE using weight loss, SEM, and Fourier transform infrared

and particle size for the laccase enzyme system (FTIR) analysis. Consistent with the present study, the

Figure 9. Microscopic images of untreated/control low-density polyethylene films (1 × 1 cm). Magnifications: ×50 (left); ×100 (middle); ×150 (right).

Volume 2 Issue 3 (2025) 7 doi: 10.36922/EER025220042