Page 22 - ESAM-1-2

P. 22

Engineering Science in

Additive Manufacturing AM-CFRP structures for EMWA properties

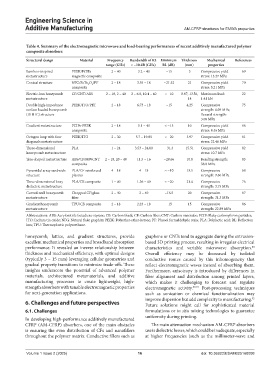

Table 4. Summary of the electromagnetic microwave and load‑bearing performances of recent additively manufactured polymer

composite absorbers

Structural design Material Frequency Bandwidth of RL Minimum Thickness Mechanical References

range (GHz) < −10 dB (GHz) RL (dB) (mm) properties

Bamboo-inspired PEEK/FCIPs 2 – 40 3.2 – 40 −15 3 Compressive yield 69

metastructure magnetic composite stress: 13.27 MPa

Conical structure NFG/Si/Fe O /PF 2 – 18 3.55 – 18 −21.52 21 Compressive yield 70

4

3

composite stress: 5.21 MPa

Electric-loss honeycomb CF/CNT/ABS 2 – 18, 2 – 40 2 – 6.8, 10.4 – 40 < −10 8.67, 13.56, Maximum load: 22

metastructure 14 1.41 kN

Double high-impedance PEEK/ITO/PET 2 – 18 6.73 – 18 −15 4.25 Compressive 75

surface-loaded honeycomb strength: 6.09 MPa;

(DHHC) structure flexural strength:

3.08 MPa

Gradient metastructure FCIPs-PEEK 2 – 18 5.1 – 40 < −15 10 Compressive yield 66

composite stress: 8.46 MPa

Octagon loop with four PEEK/ITO 2 – 30 5.7 – 19.85 < −20 3.97 Compressive yield 81

diagonals metastructure stress: 22.46 MPa

Three-dimensional PLA 1 – 24 3.53 – 24.00 −31.3 15.51 Compressive yield 82

honeycomb metastructure stress: 10.7 MPa

Tree-shaped metastructure ABS/CF/MWCNT 2 – 18, 20 – 40 11.5 – 16 −28.66 10.8 Bending strength: 83

composite 38.8 MPa

Pyramidal array sandwich PLA/CF-reinforced 4 – 18 4 – 18 ≈ −10 13.5 Compressive 68

structure plastics strength: 9.60 MPa

Three-dimensional lossy PLA/CB composite 1 – 40 1.36 – 40 < −20 21.4 Compressive 76

dielectric metastructure strength: 3.75 MPa

Curved-wall honeycomb Chopped CF/glass 2 – 40 2 – 40 −16.5 20 Compressive 87

metastructure fiber strength: 31.3 MPa

Gradient honeycomb TPU/CB composite 2 – 18 2.23 – 18 −15 15 Compressive 86

metastructure strength: 22.89 MPa

Abbreviations: ABS: Acrylonitrile butadiene styrene; CB: Carbon black; CF: Carbon fiber; CNT: Carbon nanotube; FCIP: Flaky carbonyl iron particles;

ITO: Indium tin oxide; NFG: Natural flake graphite; PEEK: Polyether-ether-ketone; PF: Phenol formaldehyde resin; PLA: Polylactic acid; RL: Reflection

loss; TPU: Thermoplastic polyurethane.

honeycomb, lattice, and gradient structures, provide graphene or CNTs tend to aggregate during the extrusion-

excellent mechanical properties and broadband absorption based 3D printing process, resulting in irregular electrical

performance. It revealed an inverse relationship between characteristics and variable microwave absorption.

88

thickness and mechanical efficiency, with optimal designs Overall efficiency may be decreased by isolated

(typically 3 – 15 mm) leveraging cellular geometries and conductive routes caused by this inhomogeneity that

gradual property transitions to minimize trade-offs. These reflect electromagnetic waves instead of absorbing them.

insights underscore the potential of advanced polymer Furthermore, anisotropy is introduced by differences in

materials, architectured metamaterials, and additive fiber alignment and distribution among printed layers,

manufacturing processes to create lightweight, high- which makes it challenging to forecast and regulate

strength absorbers with tunable electromagnetic properties electromagnetic activity. 89-91 Post-processing techniques

for next-generation applications. such as sonication or chemical functionalization may

92

improve dispersion but add complexity to manufacturing.

6. Challenges and future perspectives Future solutions might call for sophisticated material

6.1. Challenges formulations or in situ mixing technologies to guarantee

uniformity during printing.

In developing high-performance additively manufactured

CFRP (AM-CFRP) absorbers, one of the main obstacles The main attenuation mechanism AM-CFRP absorbers

is ensuring the even distribution of CFs and nanofillers use is dielectric losses, which could be inadequate, especially

throughout the polymer matrix. Conductive fillers such as at higher frequencies (such as the millimeter-wave and

Volume 1 Issue 2 (2025) 16 doi: 10.36922/ESAM025160008