Page 90 - ESAM-1-2

P. 90

Engineering Science in

Additive Manufacturing Porous structure performance improvement

A B

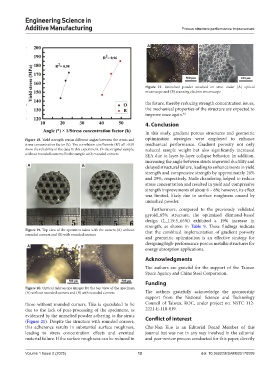

Figure 21. Unmelted powder attached on strut under (A) optical

microscope and (B) scanning electron microscope

the future, thereby reducing strength concentration issues,

the mechanical properties of the structure are expected to

improve once again. 42

4. Conclusion

In this study, gradient porous structures and geometric

Figure 18. Yield strength versus different angles between the struts and optimization strategies were employed to enhance

2

stress concentration factor (k). The correlation coefficients (R ) all >0.95 mechanical performance. Gradient porosity not only

show the reliability of the data in this experiment. O=the original sample, reduced sample weight but also significantly increased

without rounded corners; R=the sample with rounded corners. SEA due to layer-by-layer collapse behavior. In addition,

increasing the angle between struts improved ductility and

A B delayed structural failure, leading to enhancements in yield

strength and compressive strength by approximately 26%

and 29%, respectively. Node chamfering helped to reduce

stress concentration and resulted in yield and compressive

strength improvements of about 6 – 8%; however, its effect

was limited, likely due to surface roughness caused by

unmelted powder.

Furthermore, compared to the previously validated

gyroid_65% structure, the optimized diamond-based

design (L_119.5_65%) exhibited a 19% increase in

strength, as shown in Table 9. These findings indicate

Figure 19. Top view of the specimen taken with the camera (A) without that the combined implementation of gradient porosity

rounded corners and (B) with rounded corners

and geometric optimization is an effective strategy for

designing high-performance porous metallic structures for

A B

energy absorption applications.

Acknowledgments

The authors are grateful for the support of the Taiwan

Space Agency and China Steel Corporation.

Funding

Figure 20. Optical microscope images for the top view of the specimen

(A) without rounded corners and (B) with rounded corners The authors gratefully acknowledge the sponsorship

support from the National Science and Technology

those without rounded corners. This is speculated to be Council of Taiwan, ROC, under project no. NSTC 112-

due to the lack of post-processing of the specimens, as 2221-E-110-019.

evidenced by the unmelted powder adhering to the struts

(Figure 21). Despite the structure with rounded corners, Conflict of interest

this adherence results in substantial surface roughness, Che-Nan Kuo is an Editorial Board Member of this

leading to stress concentration effects and eventual journal but was not in any way involved in the editorial

material failure. If the surface roughness can be reduced in and peer-review process conducted for this paper, directly

Volume 1 Issue 2 (2025) 12 doi: 10.36922/ESAM025170009