Page 87 - IJAMD-2-3

P. 87

International Journal of AI for

Materials and Design SHM using improved CNT-BP and LSTM-NN

The properties of CNTs are as follows: density of for structural health monitoring applications of isotropic

2

2100 kg/cu.m, specific surface area of 200 m /g, and or anisotropic materials.

4

conductivity >10 S /m. The experimental setup for

fabricating the CNT-BP consists of a sonicator, a filtering 4. LSTM neural network

setup equipped with vacuum pump that creates the The LSTM neural network was employed in this study

controlled and pre-determined vacuum for sucking the for prognosis of the metallic plate under fatigue loading.

liquid, metallic plates that house the CNT-BP, a vacuum This type of neural network accurately predicts the time-

oven that is used to cure the CNT-BP, and the CNTs. The series data with information fusion capabilities exhibiting

filter membrane is Deschem with an outer diameter (OD) multiple-input multiple-output (MIMO) and left/right

of 150 mm and a membrane of cellulose acetate with cracks under propagation. It also facilitates the alleviation of

thickness of 45 µm. the gradient vanishing problem in recurrent neural network

For the fabrication procedure, 300 mg of MWCNT by incorporating LSTM unit, thereby having enhanced

were mixed in 30 mL of methanol solution and 3 mL of prediction accuracy. 22-25 A schematic illustration of the

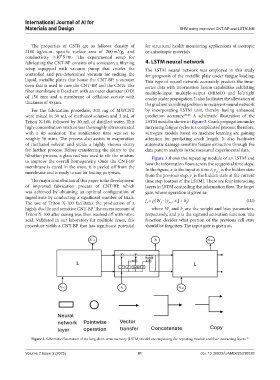

Triton X-100, followed by 30 mL of distilled water. This LSTM model is shown in Figure 3. Crack propagation under

high-concentration mixture was thoroughly ultrasonicated increasing fatigue cycles is a complicated process; therefore,

with a tip sonicator. The sonification time was set to surrogate models based on machine learning are gaining

roughly 30 mins. The process also assists in evaporation attention for predicting crack length. It also facilitates

of methanol solvent and yields a highly viscous slurry automatic damage-sensitive feature extraction through the

for further process. Before transferring the slurry to the data pattern analysis in the measured experimental data.

filtration process, a glass rod was used to stir the mixture Figure 3 shows the repeating module of an LSTM and

to improve the overall homogeneity. Once the CNT-BP how the information flows across the sequential time steps.

membrane is cured in the oven, it is peeled off from the In the figure, x is the input at time t, y is the hidden state

membrane and is ready to use for testing purposes. t t−1

from the previous step, y is the hidden state at the current

t

The major contribution of this paper is the development time step (output of the LSTM). There are four interacting

of improved fabrication process of CNT-BP, which layers in LSTM controlling the information flow. The forget

was achieved by obtaining an optimal configuration of gate, whose operation is given as:

ingredients by conducting a significant number of trials. f = ρ(W ⋅ [y , x ] + b) (III)

The use of Triton X-100 facilitates the production of a t f t−1 t f

highly ductile and sensitive CNT-BP. The excess amount of where W and b are the weight and bias parameters,

f

f

Triton X-100 after curing was then washed off with nitric respectively, and ρ is the sigmoid activation function. The

acid. Validated in our laboratory for multiple times, this function decides what portion of the previous cell state

procedure yields a CNT-BP that has significant potential should be forgotten. The input gate is given as,

Figure 3. Schematic illustration of the long short-term memory (LSTM) model encompassing the repeating module and four interacting layers. 26

Volume 2 Issue 3 (2025) 81 doi: 10.36922/IJAMD025310028