Page 291 - IJB-10-1

P. 291

International Journal of Bioprinting Scaffolds manufacturing by fused deposition modeling

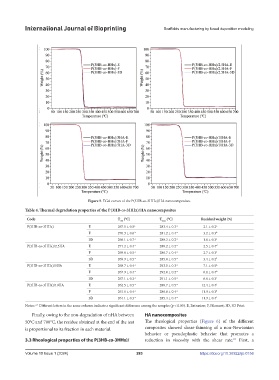

Figure 5. TGA curves of the P(3HB-co-3HHx)/HA nanocomposites.

Table 4. Thermal degradation properties of the P(3HB-co-3HHx)/HA nanocomposites

Code T (°C) T (°C) Residual weight (%)

5% max

P(3HB-co-3HHx) E 267.5 ± 0.5 a 283.4 ± 0.3 a 2.1 ± 0.2 a

F 270.3 ± 0.6 a 281.2 ± 0.4 a 3.2 ± 0.3 b

3D 266.1 ± 0.7 a 280.3 ± 0.2 a 1.8 ± 0.3 c

P(3HB-co-3HHx)/2.5HA E 271.2 ± 0.4 a 288.2 ± 0.2 a 2.5 ± 0.4 d

F 269.8 ± 0.5 a 286.7 ± 0.4 a 2.7 ± 0.3 e

3D 269.9 ± 0.5 a 285.8 ± 0.5 a 3.4 ± 0.2 f

P(3HB-co-3HHx)/5HA E 268.7 ± 0.4 a 293.5 ± 0.3 a 7.1 ± 0.5 g

F 267.9 ± 0.4 a 292.0 ± 0.2 a 6.8 ± 0.4 h

3D 267.1 ± 0.3 a 291.1 ± 0.5 a 6.6 ± 0.3 i

P(3HB-co-3HHx)/10HA E 262.5 ± 0.5 a 288.7 ± 0.5 a 12.4 ± 0.4 j

F 261.6 ± 0.4 a 286.8 ± 0.4 a 11.9 ± 0.3 k

3D 261.1 ± 0.3 a 285.4 ± 0.4 a 11.9 ± 0.4 l

Notes: Different letters in the same column indicate a significant difference among the samples (p < 0.05). E, Extrusion; F, Filament; 3D, 3D Print.

a–l

Finally, owing to the non-degradation of nHA between HA nanocomposites

50°C and 700°C, the residue obtained at the end of the test The rheological properties (Figure 6) of the different

is proportional to its fraction in each material. composites showed shear-thinning of a non-Newtonian

behavior or pseudoplastic behavior that promotes a

3.3 Rheological properties of the P(3HB-co-3HHx)/ reduction in viscosity with the shear rate. First, a

81

Volume 10 Issue 1 (2024) 283 https://doi.org/10.36922/ijb.0156