Page 294 - IJB-10-1

P. 294

International Journal of Bioprinting Scaffolds manufacturing by fused deposition modeling

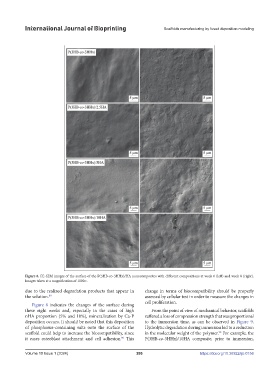

Figure 8. FE-SEM images of the surface of the P(3HB-co-3HHx)/HA nanocomposites with different compositions at week 0 (left) and week 8 (right).

Images taken at a magnification of 1000×.

due to the realized degradation products that appear in change in terms of biocompatibility should be properly

the solution. 89 assessed by cellular test in order to measure the changes in

Figure 8 indicates the changes of the surface during cell proliferation.

these eight weeks and, especially in the cases of high From the point of view of mechanical behavior, scaffolds

nHA proportion (5% and 10%), mineralization by Ca-P suffered a loss of compression strength that was proportional

deposition occurs. It should be noted that this deposition to the immersion time, as can be observed in Figure 9.

of phosphorus-containing salts onto the surface of the Hydrolytic degradation during immersion led to a reduction

scaffold could help to increase the biocompatibility, since in the molecular weight of the polymer. For example, the

90

it eases osteoblast attachment and cell adhesion. This P(3HB-co-3HHx)/10HA composite, prior to immersion,

90

Volume 10 Issue 1 (2024) 286 https://doi.org/10.36922/ijb.0156