Page 39 - IJB-3-1

P. 39

Hyeong-jin Lee, Young Won Koo, Miji Yeo, et al.

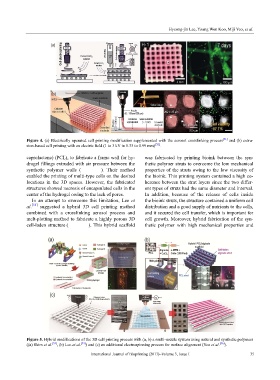

Figure 4. (a) Electrically operated cell printing modification supplemented with the aerosol crosslinking process [51] and (b) extru-

sion-based cell printing with an electric field (1 to 3 kV in 0.33 to 0.99 mm) [52] .

caprolactone) (PCL), to fabricate a frame wall for hy- was fabricated by printing bioink between the syn-

drogel fillings extruded with air pressure between the thetic polymer struts to overcome the low mechanical

synthetic polymer walls (Figure 5a). Their method properties of the struts owing to the low viscosity of

enabled the printing of multi-type cells on the desired the bioink. This printing system contained a high co-

locations in the 3D spaces. However, the fabricated herence between the strut layers since the two differ-

structures showed necrosis of encapsulated cells in the ent types of struts had the same diameter and interval.

center of the hydrogel owing to the lack of pores. In addition, because of the release of cells inside

In an attempt to overcome this limitation, Lee et the bioink struts, the structure contained a uniform cell

al. [54] suggested a hybrid 3D cell printing method distribution and a good supply of nutrients to the cells,

combined with a crosslinking aerosol process and and it secured the cell transfer, which is important for

melt-plotting method to fabricate a highly porous 3D cell growth. Moreover, hybrid fabrication of the syn-

cell-laden structure (Figure 5b). This hybrid scaffold thetic polymer with high mechanical properties and

Figure 5. Hybrid modifications of the 3D cell printing process with (a, b) a multi-nozzle system using natural and synthetic polymers

((a) Shim et al. [53] , (b) Lee et al. [54] ) and (c) an additional electrospinning process for surface alignment (Yeo et al. [56] ).

International Journal of Bioprinting (2017)–Volume 3, Issue 1 35