Page 60 - IJB-3-2

P. 60

Printing amphotericin B on microneedles using matrix-assisted pulsed laser evaporation

ment of cutaneous fungal infections involves the use In a previous paper, piezoelectric inkjet printing

of transdermal drug delivery devices. Microneedles was used to deposit amphotericin B on the surfaces of

are 50 µm- to 1 mm-long lancet-shaped devices that Gantrez® 169 BF microneedles that were created using

may be used to directly deliver amphotericin B to the a combination with visible light dynamic mask micro-

site of infection [6,7] . These devices are used to create stereolithography and micromolding. The amphotericin

pathways in the keratinized stratum corneum layer of B-loaded microneedles exhibited antifungal activity

the skin, which commonly prevents the movement of against the yeast Candida parapsilosis [11] . It should

[8]

pharmacological agents through the skin . Due to the be noted that coating thickness in piezoelectric inkjet

small dimensions of microneedles, tissue damage at the printing and many other conventional processes is not

treatment site is minimized. Microneedles are associated well controlled; for example, surface wetting may affect

with low levels of pain since they do not penetrate coating thickness [12,13] .

deeper portions of the dermis layer of the skin, where In this paper, we printed amphotericin B onto the

[9]

many large nerve endings are found . surfaces of polyglycolic acid microneedle arrays using

One of the challenges associated with developing matrix-assisted pulsed laser evaporation [14–18] . Matrix-

novel amphotericin B drug delivery methods is that assisted pulsed laser evaporation process involves laser

amphotericin B exhibits poor solubility in aqueous ablation of a frozen target that contains an amount of

solutions at physiological pH values [1,2] . Amphotericin diluted pharmacological agent in a volatile solvent [14–18] .

B exhibits amphipathic behavior because of the apolar The dimethyl sulfoxide solvent is relatively volatile,

and polar components of the lactone ring. Due to its possesses a high vapor pressure, and preferentially

amine and carboxyl groups, amphotericin B exhibits absorbs the laser energy. The dimethyl sulfoxide mo-

amphoteric behavior. As a result of these features, lecules do not deposit on the substrate due to their low

amphotericin B is insoluble in many organic solvents sticking coefficients. The amphotericin B molecules

and aqueous solvents. Several formulations have been at the gas–matrix interface are ejected when kinetic

developed to reduce amphotericin B toxicity, such energy is transferred during collisions with the solvent

as methyl ester and lipid conjugate (e.g., colloidal molecules. The less volatile amphotericin B molecules

dispersion, lipid complex, and liposome) forms [3–5] . For deposit on the substrate and form the vast majority of the

example, several lipid-containing formulations, including coating.

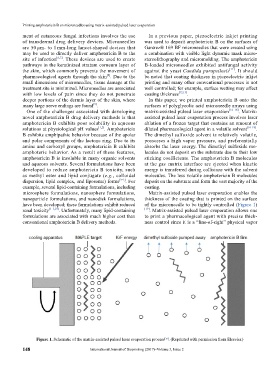

microsphere formulations, nanosphere formulations, Matrix-assisted pulsed laser evaporation enables the

nanoparticle formulations, and nanodisk formulations, thickness of the coating that is printed on the surface

have been developed; these formulations exhibit reduced of the microneedle to be tightly controlled (Figure 1)

renal toxicity [3–5,10] . Unfortunately, many lipid-containing [19] . Matrix-assisted pulsed laser evaporation allows one

formulations are associated with much higher cost than to print a pharmacological agent with precise thick-

conventional amphotericin B delivery methods. ness control since it is a “line-of-sight” physical vapor

Figure 1. Schematic of the matrix-assisted pulsed laser evaporation process . (Reprinted with permission from Elsevier.)

[19]

148 International Journal of Bioprinting (2017)–Volume 3, Issue 2