Page 293 - IJB-10-3

P. 293

International Journal of Bioprinting Design and optimization of 3DP bioscaffolds

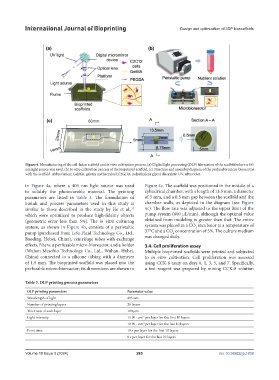

Figure 4. Manufacturing of the cell-laden scaffold and in vitro cultivation process. (a) Digital light processing (DLP) fabrication of the scaffold where a 405

nm light source was used. (b) In vitro cultivation process of the bioprinted scaffold. (c) Structure and assembly diagram of the perfusable micro-bioreactor

with the scaffold. Abbreviation: GelMA, gelatin methacryloyl; PEGDA, polyethylene glycol diacrylate; UV, ultraviolet.

in Figure 4a, where a 405 nm light source was used Figure 4c. The scaffold was positioned in the middle of a

to solidify the photocurable material. The printing cylindrical chamber, with a length of 13.5 mm, a diameter

parameters are listed in Table 3. The formulation of of 5 mm, and a 0.5 mm gap between the scaffold and the

bioink and process parameters used in this study is chamber walls, as depicted in the diagram (see Figure

similar to those described in the study by He et al., 4c). The flow rate was adjusted to the upper limit of the

15

which were optimized to produce high-fidelity objects pump system (600 µL/min), although the optimal value

(geometric error less than 5%). The in vitro culturing obtained from modeling is greater than that. The entire

system, as shown in Figure 4b, consists of a peristaltic system was placed in a CO incubator at a temperature of

2

pump (purchased from Lefu Fluid Technology Co., Ltd., 37°C and a CO concentration of 5%. The culture medium

2

Baoding, Hebei, China), centrifuge tubes with exchange was changed daily.

effects, filters, a perfusable micro-bioreactor, and a holder 3.4. Cell proliferation assay

(Wuhan Mesobio Technology Co., Ltd., Wuhan, Hubei, Multiple bioprinted scaffolds were printed and subjected

China) connected to a silicone tubing with a diameter to in vitro cultivation. Cell proliferation was assessed

of 1.5 mm. The bioprinted scaffold was placed into the using CCK-8 assay on days 0, 1, 3, 5, and 7. Specifically,

perfusable micro-bioreactor; its dimensions are shown in a test reagent was prepared by mixing CCK-8 solution

Table 3. DLP printing process parameters

DLP printing parameters Parameter value

Wavelength of light 405 nm

Number of printing layers 20 layers

Thickness of each layer 100 µm

Light intensity 15 W · cm per layer for the first 10 layers

-2

10 W · cm per layer for the last 10 layers

-2

Print time 10 s per layer for the first 10 layers

8 s per layer for the last 10 layers

Volume 10 Issue 3 (2024) 285 doi: 10.36922/ijb.1838