Page 420 - IJB-10-5

P. 420

International Journal of Bioprinting Stability of 3D-printed PEO tablets

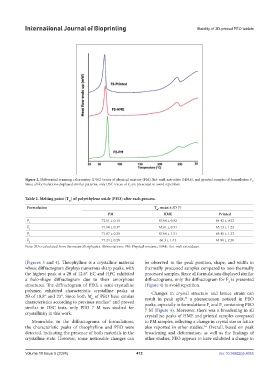

Figure 2. Differential scanning calorimetry (DSC) traces of physical mixture (PM), hot-melt extrudate (HME), and printed samples of formulation F .

2

Since all formulations displayed similar patterns, only DSC traces of F are presented to avoid repetition.

2

Table 2. Melting point (T ) of polyethylene oxide (PEO) after each process.

m

Formulation T , mean ± SD (°)

m

PM HME Printed

F 72.11 ± 0.15 67.06 ± 0.82 64.42 ± 0.32

1

F 71.18 ± 0.37 65.61 ± 0.51 65.13 ± 1.22

2

F 71.87 ± 0.25 67.06 ± 1.51 65.41 ± 1.33

3

F 71.24 ± 0.28 66.3 ± 1.43 64.86 ± 2.30

4

Note: SD is calculated from the mean of triplicates. Abbreviations: PM: Physical mixture; HME: Hot-melt extrudates.

(Figures 3 and 4). Theophylline is a crystalline material be observed in the peak position, shape, and width in

whose diffractogram displays numerous sharp peaks, with thermally processed samples compared to non-thermally

the highest peak at a 2θ of 12.6°. EC and HPC exhibited processed samples. Since all formulations displayed similar

a halo-shape diffractogram due to their amorphous diffractograms, only the diffractogram for F is presented

2

structures. The diffractogram of PEO, a semi-crystalline (Figure 4) to avoid repetition.

polymer, exhibited characteristic crystalline peaks at Changes in crystal structure and lattice strain can

2θ of 18.8° and 23°. Since both M of PEO have similar result in peak split, a phenomenon noticed in PEO

32

w

characteristics according to previous studies and proved peaks, especially in formulations F and F containing PEO

11

similar in DSC tests, only PEO 7 M was studied for 7 M (Figure 4). Moreover, there was a broadening in all

1

3

crystallinity in this work.

crystalline peaks of HME and printed samples compared

Meanwhile, in the diffractograms of formulations, to PM samples, reflecting a change in crystal size or lattice

the characteristic peaks of theophylline and PEO were also reported in other studies. Overall, based on peak

3,6

detected, indicating the presence of both materials in the broadening and deformation, as well as the findings of

crystalline state. However, some noticeable changes can other studies, PEO appears to have exhibited a change in

Volume 10 Issue 5 (2024) 412 doi: 10.36922/ijb.4055