Page 84 - IJB-6-1

P. 84

Hydrolytic expansion accelerates Fe biodegradation

A B

C

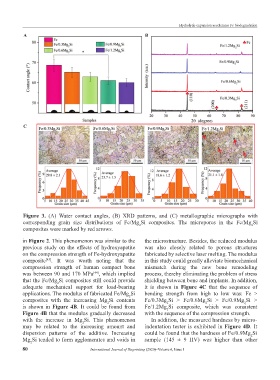

Figure 3. (A) Water contact angles, (B) XRD patterns, and (C) metallographic micrographs with

corresponding grain size distributions of Fe/Mg Si composites. The micropores in the Fe/Mg Si

2

2

composites were marked by red arrows.

in Figure 2. This phenomenon was similar to the the microstructure. Besides, the reduced modulus

previous study on the effects of hydroxyapatite was also closely related to porous structures

on the compression strength of Fe-hydroxyapatite fabricated by selective laser melting. The modulus

composite . It was worth noting that the in this study could greatly alleviate biomechanical

[43]

compression strength of human compact bone mismatch during the new bone remodeling

was between 90 and 170 MPa , which implied process, thereby eliminating the problem of stress

[44]

that the Fe/Mg Si composites still could provide shielding between bone and implants. In addition,

2

adequate mechanical support for load-bearing it is shown in Figure 4C that the sequence of

applications. The modulus of fabricated Fe/Mg Si bending strength from high to low was: Fe >

2

composites with the increasing Mg Si contents Fe/0.3Mg Si > Fe/0.6Mg Si > Fe/0.9Mg Si >

2

2

2

2

is shown in Figure 4B. It could be found from Fe/1.2Mg Si composite, which was consistent

2

Figure 4B that the modulus gradually decreased with the sequence of the compression strength.

with the increase in Mg Si. This phenomenon In addition, the measured hardness by micro-

2

may be related to the increasing amount and indentation tester is exhibited in Figure 4D. It

dispersion patterns of the additive. Increasing could be found that the hardness of Fe/0.9Mg Si

2

Mg Si tended to form agglomerates and voids in sample (145 ± 9 HV) was higher than other

2

80 International Journal of Bioprinting (2020)–Volume 6, Issue 1