Page 39 - IJB-7-1

P. 39

Attarilar, et al.

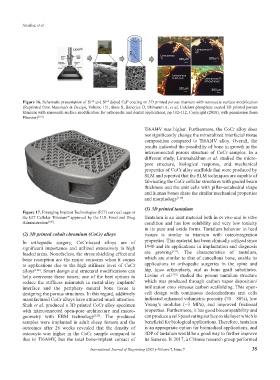

Figure 16. Schematic presentation of Sr and Si doped CaP coating on 3D printed porous titanium with nanoscale surface modification

+4

+2

(Reprinted from Materials & Design, Volume 151, Bose S, Banerjee D, Shivaram A, et al, Calcium phosphate coated 3D printed porous

titanium with nanoscale surface modification for orthopedic and dental applications, pp 102-112, Copyright (2018), with permission from

Elsevier) [119] .

Ti6Al4V was higher. Furthermore, the CoCr alloy does

not significantly change the mineralized interfacial tissue

composition compared to Ti6Al4V alloy. Overall, the

results indicated the possibility of bone in growth in the

interconnected porous structure of CoCr samples. In a

different study, Limmahakhun et al. studied the micro-

pore structure, biological response, and mechanical

properties of CoCr alloy scaffolds that were produced by

SLM and reported that the SLM techniques are capable of

fabricating the CoCr cellular structures with graded beam

thickness and the unit cells with pillar-octahedral shape

and human bones share the similar mechanical properties

and morphology [130] .

(3) 3D printed tantalum

Figure 17. Emerging Implant Technologies (EIT) cervical cage or

the EIT Cellular Titanium approved by the U.S. Food and Drug Tantalum is an inert material both in in vivo and in vitro

®

Administration [126] . condition and has low solubility and very low toxicity

in its pure and oxide forms. Tantalum behavior in hard

(2) 3D printed cobalt chromium (CoCr) alloys tissues is similar to titanium with osteointegration

In orthopedic surgery, CoCr-based alloys are of properties. This material has been clinically utilized since

significant importance and utilized extensively in high 1940 and its applications in implantation and diagnosis

loaded areas. Nonetheless, the stress shielding effect and are growing [131] . The characteristics of tantalum,

bone resorption are the major concerns when it comes which are similar to that of cancellous bone, enable its

to applications due to the high stiffness level of CoCr applications in orthopedic surgeries in the spine and

alloys [128] . Smart design and structural modifications can hip, knee arthroplasty, and as bone graft substitutes.

help overcome these issues; one of the best options to Levine et al. [132] studied the porous tantalum structure

reduce the stiffness mismatch in metal-alloy implants’ which was produced through carbon vapor deposition/

interface and the periphery natural bone tissue is infiltration onto vitreous carbon scaffolding. This open-

designing the porous structures. In this regard, additively cell design with continuous dodecahedrons unit cells

manufactured CoCr alloys have attracted much attention. indicated enhanced volumetric porosity (70 – 80%), low

Shah et al. produced a 3D printed CoCr alloy specimen Young’s modulus (~3 MPa), and improved frictional

with interconnected open-pore architecture and macro- properties. Furthermore, it has good biocompatibility and

geometry with EBM technology [129] . The produced can produce a self-passivating surface oxide layer which is

samples were implanted in adult sheep femora and the beneficial for biological applications. Therefore, tantalum

outcomes after 26 weeks revealed that the density of is an appropriate option for biomedical applications, and

osteocyte was higher in the CoCr sample compared to 3DP of tantalum would be a good way to further improve

that in Ti6Al4V, but the total bone-implant contact of its features. In 2017, a Chinese research group performed

International Journal of Bioprinting (2021)–Volume 7, Issue 7 35