Page 47 - IJB-7-3

P. 47

Mei, et al.

Ai

Aii

Bi

Bii

Biii

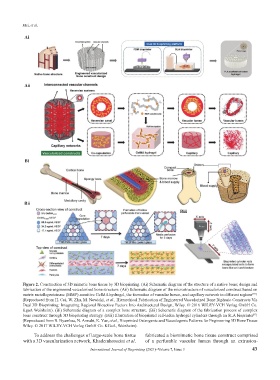

Figure 2. Construction of 3D mimetic bone tissue by 3D bioprinting. (Ai) Schematic diagram of the structure of a native bone; design and

fabrication of the engineered vascularized bone structure. (Aii) Schematic diagram of the microstructure of vascularized construct based on

matrix metalloproteinase (MMP)-sensitive GelMA hydrogel, the formation of vascular lumen, and capillary network in different regions .

[70]

(Reproduced from H. Cui, W. Zhu, M. Nowicki, et al., Hierarchical Fabrication of Engineered Vascularized Bone Biphasic Constructs Via

Dual 3D Bioprinting: Integrating Regional Bioactive Factors Into Architectural Design, Wiley. © 2016 WILEY-VCH Verlag GmbH Co.

KgaA Weinheim). (Bi) Schematic diagram of a complex bone structure. (Bii) Schematic diagram of the fabrication process of complex

bone construct through 3D bioprinting strategy. (Biii) Illustration of bioprinted cell-laden hydrogel cylinders through an SLA bioprinter .

[6]

(Reproduced from B. Byambaa, N. Annabi, K. Yue, et al., Bioprinted Osteogenic and Vasculogenic Patterns for Engineering 3D Bone Tissue

Wiley. © 2017 WILEY-VCH Verlag GmbH Co. KGaA, Weinheim).

To address the challenges of large-scale bone tissue fabricated a biomimetic bone tissue construct comprised

with a 3D vascularization network, Khademhosseini et al. of a perfusable vascular lumen through an extrusion-

International Journal of Bioprinting (2021)–Volume 7, Issue 3 43