Page 131 - IJB-8-1

P. 131

Yang, et al.

Figure 6. Scanning electron microscopy images and energy-dispersive X-ray spectroscopy patterns showing the chemical compositions of

additive manufacturing-fabricated trabecular Ta scaffolds at positions P1, P2, and P3.

A B

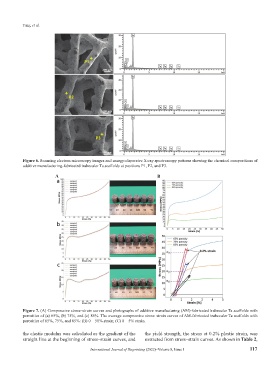

Figure 7. (A) Compressive stress–strain curves and photographs of additive manufacturing (AM)-fabricated trabecular Ta scaffolds with

porosities of (a) 65%, (b) 75%, and (c) 85%. The average compressive stress–strain curves of AM-fabricated trabecular Ta scaffolds with

porosities of 65%, 75%, and 85%: (B) 0 – 50% strain; (C) 0 – 5% strain.

the elastic modulus was calculated as the gradient of the the yield strength, the stress at 0.2% plastic strain, was

straight line at the beginning of stress–strain curves, and extracted from stress–strain curves. As shown in Table 2,

International Journal of Bioprinting (2022)–Volume 8, Issue 1 117