Page 270 - IJB-8-4

P. 270

Multifunctional 3D Bioprinting System for Construction of Complex Tissue Structure Scaffolds

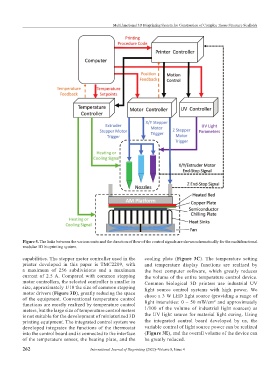

Figure 5. The links between the various units and the direction of flow of the control signals are shown schematically for the multifunctional

modular 3D bioprinting system.

capabilities. The stepper motor controller used in the cooling plate (Figure 3C). The temperature setting

printer developed in this paper is TMC2209, with and temperature display functions are realized by

a maximum of 256 subdivisions and a maximum the host computer software, which greatly reduces

current of 2.5 A. Compared with common stepping the volume of the entire temperature control device.

motor controllers, the selected controller is smaller in Common biological 3D printers use industrial UV

size, approximately 1/10 the size of common stepping light source control systems with high power. We

motor drivers (Figure 3D), greatly reducing the space chose a 3 W LED light source (providing a range of

of the equipment. Conventional temperature control light intensities: 0 – 50 mW/cm and approximately

2

functions are mostly realized by temperature control

meters, but the large size of temperature control meters 1/100 of the volume of industrial light sources) as

is not suitable for the development of miniaturized 3D the UV light source for material light curing. Using

printing equipment. The integrated control system we the integrated control board developed by us, the

developed integrates the functions of the thermostat variable control of light source power can be realized

into the control board and is connected to the interface (Figure 3E), and the overall volume of the device can

of the temperature sensor, the heating plate, and the be greatly reduced.

262 International Journal of Bioprinting (2022)–Volume 8, Issue 4