Page 90 - IJB-9-3

P. 90

International Journal of Bioprinting Biocompatible 3D printing photosensitive resin

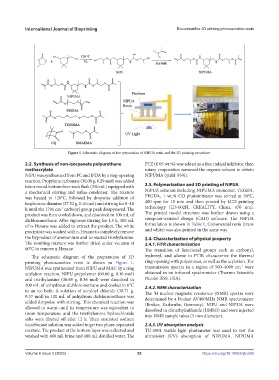

Figure 1. Schematic diagram of the preparation of NIPUA resin and the 3D printing procedure.

2.2. Synthesis of non-isocyanate polyurethane PTZ (0.05 wt.%) was added as a free radical inhibitor, then

methacrylate rotary evaporation removed the organic solvent to obtain

NIPU was synthesized from PC and IPDA by a ring-opening NIPUMA (yield: 93%).

reaction. Propylene carbonate (30.00 g, 0.29 mol) was added

into a round bottom four-neck flask (250 mL) equipped with 2.3. Polymerization and 3D printing of NIPUA

a mechanical stirring and reflux-condenser. The mixture NIPUA solution including NIPUMA monomer, TEGDA,

was heated to 120°C, followed by dropwise addition of PEGDA, 1 wt.% CQ photoinitiator was stirred at 50°C,

isophorone diamine (27.52 g, 0.16 mol) and stirring for 8–10 400 rpm for 15 min and then printed by LCD printing

h until the 1791 cm carbonyl group peak disappeared. The technology (LD-002H, CREALITY, China, 470 nm).

-1

product was then cooled down, and dissolved in 100 mL of The printed model structure was further drawn using a

dichloromethane. After vigorous stirring for 1.5 h, 300 mL computer-assisted design (CAD) software. The NIPUA

of n-Hexane was added to extract the product. The white formulation is shown in Table 1. Commercial resin (trans

precipitate was washed with n-Hexane to completely remove and white) was also printed in the same way.

the byproduct of ammonium and unreacted triethylamine. 2.4. Characterization of physical property

The resulting mixture was further dried under vacuum at 2.4.1. FITR characterization

60°C to remove n-Hexane. The transition of functional groups such as carbonyl,

The schematic diagram of the preparation of 3D hydroxyl, and alkene in FTIR characterize the thermal

printing photosensitive resin is shown in Figure 1. ring-opening with polyamines, as well as the acylation. The

-1

NIPUMA was synthesized from NIPU and MAC by a ring transmission spectra in a region of 500–4000 cm were

acylation reaction. NIPU prepolymer (60.00 g, 0.16 mol) obtained in an infrared spectrometer (Thermo Scientific

and triethylamine (36.65 g, 0.36 mol) were dissolved in Nicolet iS50, USA).

200 mL of anhydrous dichloromethane and cooled to 0°C 2.4.2. NMR characterization

in an ice bath. A solution of acryloyl chloride (38.71 g, The H nuclear magnetic resonance (NMR) spectra were

1

0.37 mol) in 100 mL of anhydrous dichloromethane was determined by a Bruker AV400MHz NMR spectrometer

added dropwise with stirring. This chemical reaction was (Bruker, Karlsruhe, Germany). NIPU and NIPUA were

allowed to warm until its temperature was equivalent to dissolved in dimethylsulfoxide (DMSO) and were injected

room temperature, and the triethylamine hydrochloride into NMR sample tubes (5 mm diameter).

salts were filtered off after 12 h. Then saturated sodium

bicarbonate solution was added to get two phase-separated 2.4.3. UV absorption analysis

mixture. The product at the bottom layer was collected and TU-1901 visible light photometer was used to test the

washed with 400 mL brine and 400 mL distilled water. The ultraviolet (UV) absorption of NIPUMA. NIPUMA

Volume 9 Issue 3 (2023) 82 https://doi.org/10.18063/ijb.684