Page 287 - IJB-9-4

P. 287

International Journal of Bioprinting 3D printing of continuous fiber reinforced PLA/PGA composites

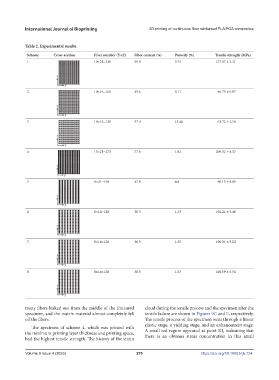

Table 2. Experimental results

Scheme Cross-section Fiber number (Y×Z) Fiber content (%) Porosity (%) Tensile strength (MPa)

1 10×21=210 59.8 3.74 127.67 ± 2.31

2 10×16=160 45.6 8.11 96.75 ± 0.87

3 10×13=130 37.0 11.48 61.72 ± 2.58

4 13×21=273 77.8 1.82 209.32 ± 8.37

5 8×21=168 47.9 4.8 96.13 ± 8.09

6 8×16=128 36.5 1.13 102.21 ± 9.46

7 8×16=128 36.5 1.35 106.01 ± 9.02

8 8×16=128 36.5 1.53 100.59 ± 5.54

many fibers leaked out from the middle of the fractured cloud during the tensile process and the specimen after the

specimen, and the matrix material almost completely fell tensile failure are shown in Figures 9C and E, respectively.

off the fibers. The tensile process of the specimen went through a linear

The specimen of scheme 4, which was printed with elastic stage, a yielding stage, and an enhancement stage.

the minimum printing layer thickness and printing space, A small red region appeared at point III, indicating that

had the highest tensile strength. The history of the strain there is an obvious stress concentration in this small

Volume 9 Issue 4 (2023) 279 https://doi.org/10.18063/ijb.734