Page 33 - IJB-9-4

P. 33

International Journal of Bioprinting Lattice-Solid hybrid 3D printing for artificial implant

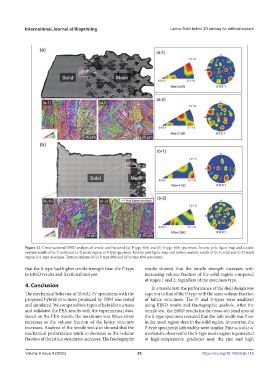

Figure 12. Cross-sectional EBSD analysis of tensile test fractured (a) P-type 40% and (b) S-type 40% specimens. Inverse pole figure map and texture

analysis results of (a-1) solid and (a-2) mesh region in P-type specimen. Inverse pole figure map and texture analysis results of (b-1) solid and (b-2) mesh

region in S-type specimen. Texture analysis of (c) P-type 40% and (d) S-type 40% specimens.

that the S-type had higher tensile strength than the P-type results showed that the tensile strength increases with

in EBSD results and fractional analysis. increasing volume fraction of the solid region composed

of stages 1 and 2, regardless of the specimen type.

4. Conclusion In a tensile test, the performance of the shell design was

The mechanical behavior of Ti-6Al-4V specimens with the superior to that of the P-type with the same volume fraction

proposed hybrid structures produced by EBM was tested of lattice structures. The P- and S-types were analyzed

and simulated. We compared two types of hybrid structures using EBSD results and fractographic analysis. After the

and validated the FEA results with the experimental data. tensile test, the EBSD results for the cross-sectional area of

Based on the FEA results, the maximum von Mises stress the S-type specimen revealed that the lath width was finer

increases as the volume fraction of the lattice structure in the mesh region than in the solid region. In contrast, the

increases. Analysis of the tensile test also showed that the P-type specimen’s lath widths were similar. Fine acicular α’

mechanical performance tends to decrease as the volume martensite observed in the S-type mesh region is generated

fraction of the lattice structures increases. The fractography at high-temperature gradients near the rim and high

Volume 9 Issue 4 (2023) 25 https://doi.org/10.18063/ijb.716