Page 425 - IJB-9-4

P. 425

International Journal of Bioprinting 3D bioprinting of artificial blood vessel

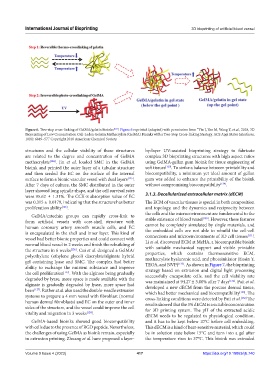

Figure 6. Two-step cross-linking of GelMA/gelatin bioinks [122] . Figure 6 reprinted (adapted) with permission from “Yin J, Yan M, Wang Y, et al., 2018, 3D

Bioprinting of Low Concentration Cell-Laden Gelatin Methacrylate (GelMA) Bioinks with a Two-Step Cross-linking Strategy. ACS Appl Mater Interfaces,

10(8): 6849–57.” Copyright 2018 American Chemical Society.

structures and the cellular viability of these structures by-layer UV-assisted bioprinting strategy to fabricate

are related to the degree and concentration of GelMA complex 3D bioprinting structures with high aspect ratios

methacrylate [124] . Jin et al. loaded SMC in the GelMA using GelMA-gellan gum bioink for tissue engineering of

bioink and printed the outer layer of a tubular structure soft tissues [129] . To strike a balance between printability and

and then seeded the EC on the surface of the internal biocompatibility, a minimum yet ideal amount of gellan

surface to form a bionic vascular vessel with dual layers [125] . gum was added to enhance the printability of the bioink

After 7 days of culture, the SMC distributed in the outer without compromising biocompatibility [129] .

layer showed long spindle shape, and the cell survival rates

were 95.62 ± 1.31%. The CCK-8 absorption value of EC 3.1.3. Decellularized extracellular matrix (dECM)

was 0.315 ± 0.0179, indicating that the structurehas better The ECM of vascular tissues is special in both composition

proliferation ability [125] . and topology, and the dynamics and reciprocity between

GelMA/catechin groups can rapidly cross-link to the cells and the microenvironment are fundamental to the

form artificial vessels with core-shell structure with stable existence of blood vessel [130] . However, these features

human coronary artery smooth muscle cells, and EC cannot be completely simulated by single materials, and

is encapsulated in the shell and inner layer. This kind of the embedded cells are not able to rebuild the cell-cell

.

connections and microenvironments of 3D cell tissues

[131]

vessel had better bionic properties and could connect with Li et al. discovered ECM at MeHA, a biocompatible bioink

normal blood vessel in 2 weeks and finish the rebuilding of with suitable mechanical support and visible printable

the structure in 6 weeks [126] . Cui et al. designed a GelMA/

polyethylene (ethylene glycol) diacrylate/alginate hybrid properties, which contains thermosensitive ECM,

gel containing lyase and SMC. The complex had better methacrylate hyaluronic acid, and photoinitiator (Eosin Y,

. As shown in Figure 7, the bioprinting

TEOA, and NVP)

[132]

ability to exchange the nutrient substance and improve strategy based on extrusion and digital light processing

the cell proliferation [127] . With the alginate being gradually successfully encapsulate cells, and the cell viability rate

degraded by lyase, more space is made available with the was maintained at 94.27 ± 3.00% after 7 days [132] . Pati et al.

alginate is gradually degraded by lyase, more space had developed a new dECM from the porcine dermal tissue,

been [127] . Ruther et al. also used the double-needle extrusion which had better mechanical and biocompatibility [133] . The

systems to prepare a 4 mm vessel with fibroblast (normal cross-linking conditions were detected by Pati et al. [132] The

human dermal fibroblasts) and EC on the outer and inner results showed that the 3% dECM is a suitable concentration

sides of the structure, and the vessel could improve the cell for 3D printing system. The pH of the extracted acidic

vitality and migration in 3 weeks [128] .

dECM needs to be regulated to physiological condition,

GelMA-based bioinks showed good biocompatibility and it has to be kept below 10°C before cell embedding.

with cells due to the presence of RGD peptide. Nevertheless, This dECM is a kind of heat-sensitive material, which could

the challenges of using GelMA as bioink remain, especially be in solution state below 15°C and turn into a gel after

in extrusion printing. Zhuang et al. have proposed a layer- the temperature rises to 37°C. This bioink was extruded

Volume 9 Issue 4 (2023) 417 https://doi.org/10.18063/ijb.740