Page 538 - IJB-9-6

P. 538

International Journal of Bioprinting High-performance SrCS scaffolds via vat photopolymerization

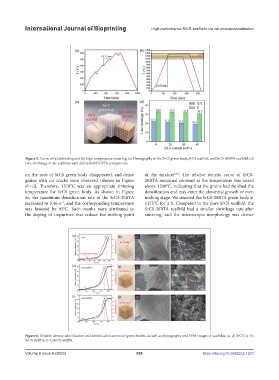

Figure 5. Curve of (a) debinding and (b) high-temperature sintering. (c) Photography of the SrCS green body, SrCS scaffold, and SrCS-40BTA scaffold. (d)

Line shrinkage of the scaffolds with different SrCS-BTA components.

[50]

on the rods of SrCS green body disappeared, and dense of the mixture . The relative density curve of SrCS-

grains with no cracks were observed (shown in Figure 20BTA remained constant as the temperature was raised

6b–d). Therefore, 1270°C was an appropriate sintering above 1200°C, indicating that the grains had finished the

temperature for SrCS green body. As shown in Figure densification and may enter the abnormal growth or even

6e, the maximum densification rate of the SrCS-20BTA melting stage. We sintered the SrCS-20BTA green body at

increased to 0.46 s , and the corresponding temperature 1175°C for 2 h. Compared to the pure SrCS scaffold, the

−1

was lowered by 95°C. Such results were attributed to SrCS-20BTA scaffold had a smaller shrinkage rate after

the doping of impurities that reduce the melting point sintering, and the microscopic morphology was denser

Figure 6. Relative density densification and densification curves of green bodies, as well as photography and SEM images of scaffolds. (a–d) SrCS; (e–h)

SrCS-20BTA; (i–l) SrCS-40BTA.

Volume 9 Issue 6 (2023) 530 https://doi.org/10.36922/ijb.1233