Page 542 - IJB-9-6

P. 542

International Journal of Bioprinting High-performance SrCS scaffolds via vat photopolymerization

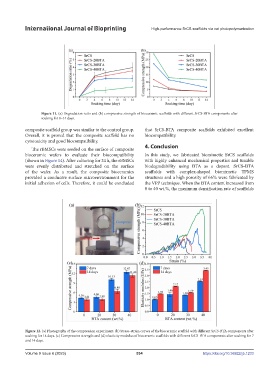

Figure 11. (a) Degradation ratio and (b) compressive strength of bioceramic scaffolds with different SrCS-BTA components after

soaking for 0–14 days.

composite scaffold group was similar to the control group. that SrCS-BTA composite scaffolds exhibited excellent

Overall, it is proved that the composite scaffold has no biocompatibility.

cytotoxicity and good biocompatibility.

The rBMSCs were seeded on the surface of composite 4. Conclusion

bioceramic wafers to evaluate their biocompatibility In this study, we fabricated biomimetic SrCS scaffolds

(shown in Figure 14). After culturing for 24 h, the rBMSCs with highly enhanced mechanical properties and tunable

were evenly distributed and stretched on the surface biodegradability using BTA as a dopant. SrCS-BTA

of the wafer. As a result, the composite bioceramics scaffolds with complex-shaped biomimetic TPMS

provided a conducive surface microenvironment for the structures and a high porosity of 66% were fabricated by

initial adhesion of cells. Therefore, it could be concluded the VPP technique. When the BTA content increased from

0 to 40 wt.%, the maximum densification rate of scaffolds

Figure 12. (a) Photography of the compression experiment. (b) Stress–strain curves of the bioceramic scaffold with different SrCS-BTA components after

soaking for 14 days. (c) Compressive strength and (d) elasticity modulus of bioceramic scaffolds with different SrCS-BTA components after soaking for 7

and 14 days.

Volume 9 Issue 6 (2023) 534 https://doi.org/10.36922/ijb.1233