Page 328 - v11i4

P. 328

International Journal of Bioprinting Nozzle geometry for enhanced cell viability

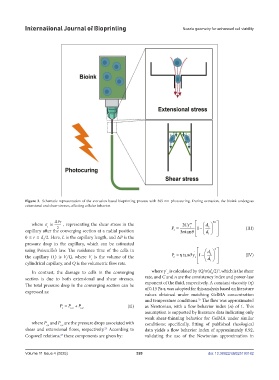

Figure 3. Schematic representation of the extrusion-based bioprinting process with 365 nm photocuring. During extrusion, the bioink undergoes

extensional and shear stresses, affecting cellular behavior.

where σ is Pr , representing the shear stress in the 2 C c n d 3 n

s

2

2

capillary after the converging section at a radial position P n 3 tan 1 d 1 (III)

s

0 ≤ r ≤ d /2. Here, L is the capillary length, and ∆P is the

2

pressure drop in the capillary, which can be estimated

using Poiseuille’s law. The residence time of the cells in . d 3

the capillary (t ) is V/Q, where V is the volume of the P tan c 1 d 2 (IV)

e

s

c

c

cylindrical capillary, and Q is the volumetric flow rate. 1

3

In contrast, the damage to cells in the converging where γ˙ is calculated by 4Q/π(d /2) , which is the shear

2

c

section is due to both extensional and shear stresses. rate, and C and n are the consistency index and power-law

The total pressure drop in the converging section can be exponent of the fluid, respectively. A constant viscosity (η)

expressed as: of 0.15 Pa·s, was adopted for this analysis based on literature

values obtained under matching GelMA concentration

and temperature conditions. The flow was approximated

25

P P P c e, (II) as Newtonian, with a flow behavior index (n) of 1. This

c s,

c

assumption is supported by literature data indicating only

weak shear-thinning behavior for GelMA under similar

where P and P are the pressure drops associated with conditions; specifically, fitting of published rheological

c,e

c,s

shear and extensional flows, respectively. According to data yields a flow behavior index of approximately 0.92,

23

Cogswell relations, these components are given by: validating the use of the Newtonian approximation in

24

Volume 11 Issue 4 (2025) 320 doi: 10.36922/IJB025190182