Page 39 - MSAM-3-4

P. 39

Materials Science in Additive Manufacturing Gyroid non-pneumatic tires through additive manufacturing

Table 3. Average maximum load-bearing capacity and bulk

stiffness for all tire design variations (n=3)

Tire sheet Average maximum Average maximum bulk

thickness load-bearing capacity (N) stiffness, kb (N/mm)

1 mm 2119.10 176.25

1 – 1.5 mm 2526.85 210.09

1 – 2 mm 3237.47 269.06

11). The minimal deformation in the L0 region indicates

high stiffness, as it withstands more load with minimal

displacement. In contrast, both the L1 and L2 regions

display a slight increase in deformation compared to L0,

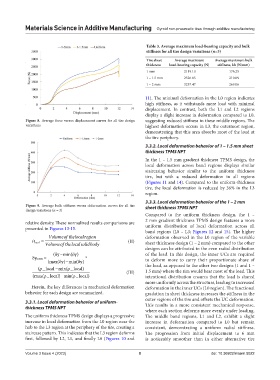

Figure 8. Average force versus displacement curves for all tire design suggesting reduced stiffness in these middle regions. The

variations highest deformation occurs in L3, the outermost region,

demonstrating that this area absorbs most of the load at

the tire periphery.

3.3.2. Local deformation behavior of 1 – 1.5 mm sheet

thickness TPMS NPT

In the 1 – 1.5 mm gradient thickness TPMS design, the

local deformation across band regions displays similar

staircasing behavior similar to the uniform thickness

tire, but with a reduced deformation in all regions

(Figures 11 and 14). Compared to the uniform-thickness

tire, the local deformation is reduced by 36% in the L3

region.

3.3.3. Local deformation behavior of the 1 – 2 mm

Figure 9. Average bulk stiffness versus deformation curves for all tire sheet thickness TPMS NPT

design variations (n = 3)

Compared to the uniform thickness design, the 1 –

relative density. These normalized results comparisons are 2 mm gradient thickness TPMS design features a more

presented in Figures 13-15. uniform distribution of local deformation across all

band regions (L0 – L3; Figures 12 and 15). The higher

Volumeof thelocalregion deformation observed in the L0 region of the variable

ρ local = Volumeof thelocalsolidbody (II) sheet thickness design (1 – 2 mm) compared to the other

designs can be attributed to the even radial distribution

( δymin( δy) of the load. In this design, the inner UCs are required

−

δynorm = *

(

( maxy) miny) to deform more to carry their proportionate share of

δ (

δ −

(_ − ρ local) the load, as opposed to the other two designs (1 and 1 –

ρ localmin(_

1.5 mm) where the rim would bear most of the load. This

( maax(_ρ local)− min( _ρ local) (III) intentional distribution ensures that the load is shared

more uniformly across the structure, leading to increased

Herein, the key differences in mechanical deformation deformation in the inner UCs (L0 region). The functional

behavior for each design are summarized. gradation in sheet thickness increases the stiffness in the

3.3.1. Local deformation behavior of uniform- outer regions of the tire and offsets the UC deformation.

thickness TPMS NPT This results in a more consistent mechanical response,

where each section deforms more evenly under loading.

The uniform thickness TPMS design displays a progressive The middle band regions, L1 and L2, exhibit a slight

increase in local deformation from the L0 region near the increase in deformation compared to L0 but remain

hub to the L3 region at the periphery of the tire, creating a consistent, demonstrating a uniform radial stiffness.

staircase pattern. This indicates that the L3 region deforms The progression from initial displacement to 6 mm

first, followed by L2, L1, and finally L0 (Figures 10 and is noticeably smoother than in either alternative tire

Volume 3 Issue 4 (2023) 8 doi: 10.36922/msam.5022