Page 40 - MSAM-3-4

P. 40

Materials Science in Additive Manufacturing Gyroid non-pneumatic tires through additive manufacturing

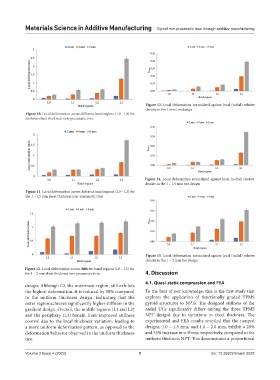

Figure 13. Local deformation normalized against local (radial) relative

density in the 1 mm tire design

Figure 10. Local deformation across different band regions (L0 – L3) for

uniform-sheet thickness non-pneumatic tires

Figure 14. Local deformation normalized against local (radial) relative

density in the 1 – 1.5 mm tire design

Figure 11. Local deformation across different band regions (L0 – L3) for

the 1 – 1.5 mm sheet thickness non-pneumatic tires

Figure 15. Local deformation normalized against local (radial) relative

density in the 1 – 2 mm tire design

Figure 12. Local deformation across different band regions (L0 – L3) for

the 1 – 2 mm sheet thickness non-pneumatic tires 4. Discussion

4.1. Quasi-static compression and FEA

design. Although L3, the outermost region, still exhibits

the highest deformation, it is reduced by 58% compared To the best of our knowledge, this is the first study that

to the uniform thickness design, indicating that the explores the application of functionally graded TPMS

outer region achieves significantly higher stiffness in the gyroid structures to NPTs. The designed stiffness of the

gradient design. Overall, the middle regions (L1 and L2) radial UCs significantly differs among the three TPMS

and the periphery (L3) benefit from improved stiffness NPT designs due to variations in sheet thickness. The

control due to the local thickness variation, leading to experimental and FEA results revealed that the ramped

a more uniform deformation pattern, as opposed to the designs, 1.0 – 1.5 mm, and 1.0 – 2.0 mm, exhibit a 20%

deformation behavior observed in the uniform thickness and 53% increase in stiffness, respectively, compared to the

tire. uniform thickness NPT. This demonstrates a proportional

Volume 3 Issue 4 (2023) 9 doi: 10.36922/msam.5022