Page 91 - MSAM-4-1

P. 91

Materials Science in Additive Manufacturing Additive manufacturing of NASA HR-1 angled walls

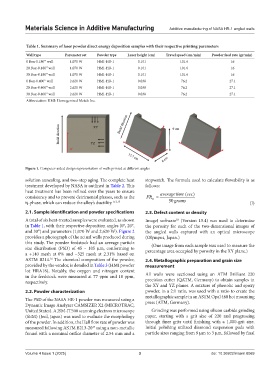

Table 1. Summary of laser powder direct energy deposition samples with their respective printing parameters

Wall type Parameter set Powder type Layer height (cm) Travel speed (cm/min) Powder feed rate (gr/min)

0 Box-0.180″ wall 1,070 W HMI-HR-1 0.101 101.6 16

20 Box-0.180″ wall 1,070 W HMI-HR-1 0.101 101.6 16

30 Box-0.180″ wall 1,070 W HMI-HR-1 0.101 101.6 16

0 Box-0.400″ wall 2,620 W HMI-HR-1 0.038 76.2 27.1

20 Box-0.400″ wall 2,620 W HMI-HR-1 0.038 76.2 27.1

30 Box-0.400″ wall 2,620 W HMI-HR-1 0.038 76.2 27.1

Abbreviation: HMI: Homogenized Metals Inc.

Figure 1. Computer-aided design representation of walls printed at different angles

solution annealing, and two-step aging. The complete heat stopwatch. The formula used to calculate flowability is as

treatment developed by NASA is outlined in Table 2. This follows:

heat treatment has been refined over the years to ensure averagetime (sec )

consistency and to prevent detrimental phases, such as the FR =

H

η-phase, which can reduce the alloy’s ductility. 1,12,15 50 grams (I)

2.1. Sample identification and powder specifications 2.3. Defect content or density

A total of six heat-treated samples were evaluated, as shown ImageJ software (Version 15.4) was used to determine

18

in Table 1, with their respective deposition angles (0°, 20°, the porosity for each of the two-dimensional images of

and 30°) and parameters (1,070 W and 2,620 W). Figure 2 the angled walls captured with an optical microscope

provides a photograph of the actual walls produced during (Olympus, Japan.)

this study. The powder feedstock had an average particle (One image from each sample was used to measure the

size distribution (PSD) of 45 – 105 µm, conforming to percentage area occupied by porosity in the XY plane.)

a +140 mesh at 0% and −325 mesh at 2.31% based on

ASTM B214. The chemical composition of the powder, 2.4. Metallographic preparation and grain size

16

provided by the vendor, is detailed in Table 3 (HMI powder measurement

lot HRA18). Notably, the oxygen and nitrogen content

in the feedstock were measured at 77 ppm and 10 ppm, All walls were sectioned using an ATM Brilliant 220

respectively. precision cutter (QATM, Germany) to obtain samples in

the XY and YZ planes. A mixture of phenolic and epoxy

2.2. Powder characterization powder, in a 2:1 ratio, was used with a ratio to create the

metallographic sample in an ASTM Opal 460 hot mounting

The PSD of the NASA HR-1 powder was measured using a press (ATM, Germany).

Dynamic Image Analyzer CAMSIZER X2 (MICROTRAC,

United States). A JSM-IT500 scanning electron microscope Grinding was performed using silicon carbide grinding

(SEM) (Jeol, Japan) was used to evaluate the morphology paper, starting with a grit size of 220 and progressing

of the powder. In addition, the Hall flow rate of powder was through finer grits until finishing with a 1,000-grit size.

measured following ASTM B213-20 using a non-metallic Initial polishing utilized diamond suspension pads with

17

funnel with a nominal orifice diameter of 2.54 mm and a particle sizes ranging from 9 µm to 3 µm, followed by final

Volume 4 Issue 1 (2025) 3 doi: 10.36922/msam.8069