Page 127 - MSAM-4-3

P. 127

Materials Science in Additive Manufacturing 3D-Printed hip joints performance

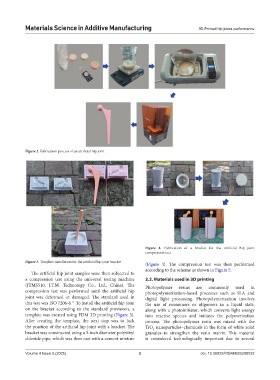

Figure 2. Fabrication process of an artificial hip joint

Figure 4. Fabrication of a bracket for the artificial hip joint

compression test

Figure 3. Template installation for the artificial hip joint bracket

(Figure 4). The compression test was then performed

according to the scheme as shown in Figure 5.

The artificial hip joint samples were then subjected to

a compression test using the universal testing machine 2.2. Materials used in 3D printing

(JTMS510, J.T.M. Technology Co., Ltd., China). The Photopolymer resins are commonly used in

compression test was performed until the artificial hip photopolymerization-based processes such as SLA and

joint was deformed or damaged. The standard used in digital light processing. Photopolymerization involves

this test was ISO 7206-6. To install the artificial hip joint the use of monomers or oligomers in a liquid state,

11

on the bracket according to the standard provisions, a along with a photoinitiator, which converts light energy

template was created using FDM 3D printing (Figure 3). into reactive species and initiates the polymerization

After creating the template, the next step was to lock process. The photopolymer resin was mixed with the

the position of the artificial hip joint with a bracket. The TiO nanoparticles–chemicals in the form of white solid

2

bracket was constructed using a 3-inch diameter polyvinyl granules–to strengthen the resin matrix. This material

chloride pipe, which was then cast with a cement mixture is considered technologically important due to several

Volume 4 Issue 3 (2025) 3 doi: 10.36922/MSAM025200032