Page 157 - MSAM-4-3

P. 157

Materials Science in Additive Manufacturing L-PBF Ti-10Ta-2Nb-2Zr: Microstructure and Strength

A

B

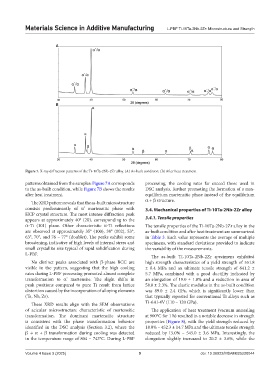

Figure 7. X-ray diffraction patterns of the Ti-10Ta-2Nb-2Zr alloy. (A) As-built condition; (B) After heat treatment

patterns obtained from the samples: Figure 7A corresponds processing, the cooling rates far exceed those used in

to the as-built condition, while Figure 7B shows the results DSC analysis, further promoting the formation of a non-

after heat treatment. equilibrium martensitic phase instead of the equilibrium

The XRD pattern reveals that the as-built microstructure α + β structure.

consists predominantly of α’ martensitic phase with 3.4. Mechanical properties of Ti-10Ta-2Nb-2Zr alloy

HCP crystal structure. The most intense diffraction peak

appears at approximately 40° (2θ), corresponding to the 3.4.1. Tensile properties

α-Ti (101) plane. Other characteristic α-Ti reflections The tensile properties of the Ti-10Ta-2Nb-2Zr alloy in the

are observed at approximately 35° (100), 38° (002), 53°, as-built condition and after heat treatment are summarized

63°, 70°, and 76 – 77° (doublet). The peaks exhibit some in Table 3. Each value represents the average of multiple

broadening, indicative of high levels of internal stress and specimens, with standard deviations provided to indicate

small crystallite size typical of rapid solidification during the variability of the measurements.

L-PBF.

The as-built Ti-10Ta-2Nb-2Zr specimens exhibited

No distinct peaks associated with β-phase BCC are high strength characteristics of a yield strength of 551.8

visible in the pattern, suggesting that the high cooling ± 8.4 MPa and an ultimate tensile strength of 641.2 ±

rates during L-PBF processing promoted almost complete 5.7 MPa, combined with a good ductility indicated by

transformation to α’ martensite. The slight shifts in an elongation of 19.0 ± 1.8% and a reduction in area of

peak positions compared to pure Ti result from lattice 58.0 ± 2.3%. The elastic modulus in the as-built condition

distortion caused by the incorporation of alloying elements was 89.0 ± 2.4 GPa, which is significantly lower than

(Ta, Nb, Zr). that typically reported for conventional Ti alloys such as

These XRD results align with the SEM observations Ti-6Al-4V (110 – 120 GPa).

of acicular microstructure characteristic of martensitic The application of heat treatment (vacuum annealing

transformation. The dominant martensitic structure at 900°C for 1 h) resulted in a notable decrease in strength

is consistent with the phase transformation behavior properties (Figure 8), with the yield strength reduced by

identified in the DSC analysis (Section 3.2), where the 18.0% – 452.3 ± 14.7 MPa and the ultimate tensile strength

β → α + β transformation during cooling was detected reduced by 15.0% – 545.0 ± 3.6 MPa. Interestingly, the

in the temperature range of 804 – 743°C. During L-PBF elongation slightly increased to 20.2 ± 3.6%, while the

Volume 4 Issue 3 (2025) 9 doi: 10.36922/MSAM025220044