Page 70 - DP-1-1

P. 70

Design+ Defect-oriented BIST for AMS circuits

sampling switch is its relatively constant Ron with respect 2.3.2. Defect-oriented BIST for SAR ADC

to the Vin. Having a relatively constant Ron is enabled by As mentioned earlier, any complex AMS circuit needs to

keeping the VGS of the main switch M1, always equal to be broken down into smaller subcircuits. As depicted in

VDD, independent of Vin. 18

Figure 2, we broke down the SAR ADC into a comparator,

The comparator for this design is a two-stage comparator capacitive DAC, and sampling switch. For each subcircuit,

including a preamplifier stage and the dynamic latch stage. we then developed a test based on the analyzed crucial

19

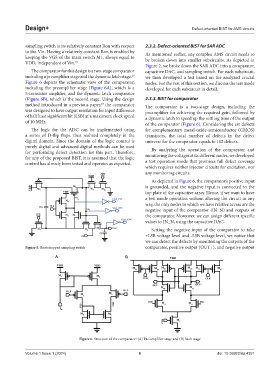

Figure 6 depicts the schematic view of the comparator, nodes. For the rest of this section, we discuss the test mode

including the preamplifier stage (Figure 6A), which is a developed for each subcircuit in detail.

5-transistor amplifier, and the dynamic latch comparator

(Figure 6B), which is the second stage. Using the design 2.3.3. BIST for comparator

method introduced in a previous paper, the comparator The comparator is a two-stage design, including the

19

was designed to have output resolution for input difference preamplifier for achieving the required gain, followed by

of half least significant bit (LSB) at a maximum clock speed a dynamic latch to speed up the settling time of the output

of 10 MHz. of the comparator (Figure 6). Considering the six defects

The logic for the ADC can be implemented using for complementary metal-oxide-semiconductor (CMOS)

a series of D-flip flops, thus realized completely in the transistors, the total number of defects in the defect

digital domain. Since the domain of the logic control is universe for the comparator equals to 102 defects.

purely digital and advanced digital methods can be used By analyzing the operation of the comparator and

for performing defect detection for this part. Therefore,

for any of the proposed BIST, it is assumed that the logic monitoring the voltages at its different nodes, we developed

control has already been tested and operates as expected. a test operation mode that promises full defect coverage

which requires neither injector circuits for excitation, nor

any monitoring circuits.

As depicted in Figure 6, the comparator’s positive input

is grounded, and the negative input is connected to the

top plate of the capacitive array. Hence, if we want to have

a test mode operation without altering the circuit in any

way, the only nodes to which we have relative access are the

negative input of the comparator (IN_N) and outputs of

the comparator. Moreover, we can assign different specific

values to IN_N, using the capacitive DAC.

Setting the negative input of the comparator to take

+LSB voltage level and -LSB voltage level, we notice that

we can detect the defects by monitoring the outputs of the

Figure 5. Bootstrapped sampling switch comparator, positive output (OUT+), and negative output

A B

Figure 6. Structure of the comparator: (A) Pre-amplifier stage and (B) latch stage

Volume 1 Issue 1 (2024) 6 doi: 10.36922/dp.4351