Page 35 - IJB-2-2

P. 35

Jia Min Lee, Swee Leong Sing, Edgar Yong Sheng Tan, et al.

bers with nanoscale features formed by electrospin- of biomaterials. It is critical to ensure that the lumen

ning [81] . Microscale geometries confine and direct cell of vasculature network does not collapse while the

growth towards anisotropic direction. However, these stiffness does not impede nutrient and waste transpor-

methods fall short in describing cell behavior in native tation across the network. Moreover, with comput-

environment. Therefore, there is a need to design 3D er-based technology, vascular system for complex or-

engineered tissue in order to utilize and integrate the gan manufacturing can be simulated and printed with-

previous findings into a 3D perspective. in a bioprinted construct [83] .

(3) Functioning Vasculature Network (4) Material Formulation

Sooppan et al. demonstrated the perfusion and Apart from designing materials to improve print fi-

anastomosis of a microchannel printed using polydi- delity in bioprinting, materials for engineering cardiac

methylsiloxane (PDMS) [82] . The integration of bio- tissue is needed to capture the physiological and functi-

printed vascular network with host tissue still remains onal properties of native cardiac tissues. Nanocompo-

hopeful. One of the major concerns is with the choice site hydrogel and electronics printing can be engineered

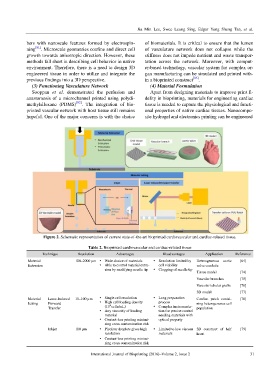

Figure 2. Schematic representation of current state-of-the-art bioprinted cardiovascular and cardiac-related tissue.

Table 2. Bioprinted cardiovascular and cardiac-related tissue

Technique Resolution Advantages Disadvantages Application Reference

Material 100–2000 µm Wide choice of materials Resolution limited by Heterogeneous aortic [64]

Extrusion Able to control material extru- cell viability valve conduits

sion by modifying needle tip Clogging of needle tip

Tissue model [74]

Vascular branches [75]

Vascular tubular grafts [76]

3D model [77]

Material Laser-Induced 10–100 µm Single cell resolution Long preparation Cardiac patch contai- [78]

Jetting Forward High cell loading density process ning heterogeneous cell

8

Transfer (10 cells/mL) Complex instrumenta- population

Any viscosity of loading tion for precise control

material needing materials with

Contact-less printing minimi- optical property

zing cross contamination risk

Inkjet 100 µm Picoliter droplets gives high Limited to low viscous 3D construct of half [79]

resolution materials heart

Contact-less printing minimi-

zing cross contamination risk

International Journal of Bioprinting (2016)–Volume 2, Issue 2 31