Page 75 - IJB-2-2

P. 75

Anatoliy Popovich, Vadim Sufiiarov, Igor Polozov, et al.

of the implant is shown in Figure 4A, while the other cooling. The microstructures of the bulk material after

possible orientation is demonstrated in Figure 4B. SLM and after the second type of heat treatment are

Then the acetabular custom-made implant was pro- shown in Figure 6. Before annealing, the microstruc-

duced by SLM out of Ti-6Al-4V powder (Figure 5). ture consists of α′-phase (Figures 6A and B), which is

The build accuracy of the manufactured titanium im- the result of high cooling rates during the SLM pro-

plant is around 200 µm. After heat treatment, the sup- cess [29] and similar to the microstructures in litera-

ports were removed from the implant, it was shot ture [30,31] . Metastable martensitic α′-phase and the α-ph-

peened, additionally cleaned, and prepared by medical ase have HCP crystalline structure. The main differ-

staff—the implant was then installed into the patient ence between them is the greater amount of vanadium

[6]

during surgery. Postoperative supervision has shown in the martensitic phase compared to the α-phase .

good results; the patient can move with the installed The material after SLM shows high tensile strength,

implant. but low elongation at break (Table 1). High tempera-

Two types of heat treatment were applied to the Ti- ture gradients during SLM result in increased thermal

6Al-4V material after SLM. Annealing was carried out stresses in the material [29] and high residual stresses in

in vacuum with the following parameters: 1) 950 °С the produced part [32,33] ; wherefore annealing is needed

for 1.5 hours; 2) 800 °С for 4 hours; both with furnace for achieving better mechanical properties and stress

(A) (B)

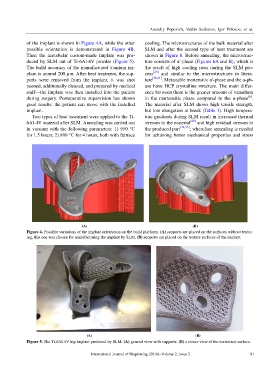

Figure 4. Possible variations of the implant orientation on the build platform: (A) supports are placed on the surfaces without textur-

ing, this one was chosen for manufacturing the implant by SLM, (B) supports are placed on the texture surfaces of the implant.

(A) (B)

Figure 5. The Ti-6Al-4V hip implant produced by SLM: (A) general view with supports; (B) a closer view of the texturized surface.

International Journal of Bioprinting (2016)–Volume 2, Issue 2 81