Page 620 - IJB-10-3

P. 620

International Journal of Bioprinting Wireless module system applied on 3D-printed implant

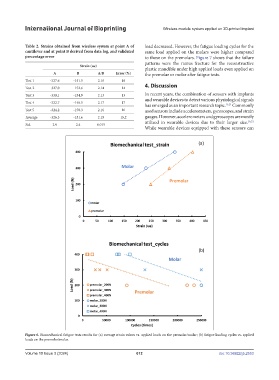

Table 2. Strains obtained from wireless system at point A of load decreased. However, the fatigue loading cycles for the

cantilever and at point B derived from data log, and validated same load applied on the molars were higher compared

percentage error to those on the premolars. Figure 7 shows that the failure

patterns were the ramus fracture for the reconstructive

Strain (ue)

plastic mandible under high applied loads even applied on

A B A/B Error (%) the premolar or molar after fatigue tests.

Test 1 -327.6 -151.5 2.16 16

Test 2 -327.0 -152.6 2.14 14 4. Discussion

Test 3 -330.1 -154.9 2.13 13 In recent years, the combination of sensors with implants

and wearable devices to detect various physiological signals

Test 4 -322.7 -148.5 2.17 17

has emerged as an important research topic. 16,21 Commonly

Test 5 -324.2 -150.3 2.16 16 used sensors include accelerometers, gyroscopes, and strain

Average -326.3 -151.6 2.15 15.2 gauges. However, accelerometers and gyroscopes are mostly

utilized in wearable devices due to their larger size. 16,21

Std. 2.9 2.4 0.015

While wearable devices equipped with these sensors can

Figure 6. Biomechanical fatigue tests results for (a) average strain values vs. applied loads on the premolar/molar; (b) fatigue loading cycles vs. applied

loads on the premolar/molar.

Volume 10 Issue 3 (2024) 612 doi: 10.36922/ijb.2553