Page 202 - IJB-9-5

P. 202

International Journal of Bioprinting Using droplet jetting for bioprinting

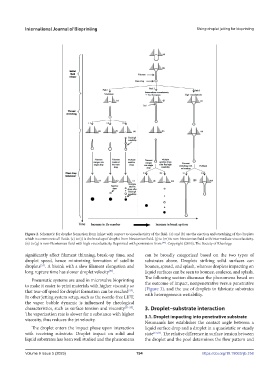

Figure 2. Schematic for droplet formation from inkjet with respect to viscoelasticity of the fluid. (a) and (b) are the ejection and stretching of the droplets

which is common to all fluids. (c) to (i) is the breakup of droplet from Newtonian fluid. (j) to (m) is non-Newtonian fluid with intermediate viscoelasticity.

(n) to (q) is non-Newtonian fluid with high viscoelasticity. Reprinted with permission from . Copyright (2010), The Society of Rheology.

[49]

significantly affect filament thinning, break-up time, and can be broadly categorized based on the two types of

droplet speed, hence minimizing formation of satellite substrates above. Droplets striking solid surfaces can

droplets . A bioink with a slow filament elongation and bounce, spread, and splash, whereas droplets impacting on

[53]

long rupture time has slower droplet velocity . liquid surfaces can be seen to bounce, coalesce, and splash.

[54]

The following section discusses the phenomena based on

Pneumatic systems are used in microvalve bioprinting

to make it easier to print materials with higher viscosity so the outcome of impact, nonpenetrative versus penetrative

(Figure 3), and the use of droplets to fabricate substrates

[55]

that tear-off speed for droplet formation can be reached . with heterogeneous wettability.

In other jetting system setup, such as the nozzle-free LIFT,

the vapor bubble dynamic is influenced by rheological

characteristics, such as surface tension and viscosity [31-33] . 3. Droplet–substrate interaction

The vaporization rate is slower for a substance with higher 3.1. Droplet impacting into penetrative substrate

viscosity, thus reduces the jet velocity.

Neumann’s law establishes the contact angle between a

The droplet enters the impact phase upon interaction liquid surface drop and a droplet in a quasistatic or steady

with receiving substrate. Droplet impact on solid and state [61,62] . The relative difference in surface tension between

liquid substrates has been well studied and the phenomena the droplet and the pool determines the flow pattern and

Volume 9 Issue 5 (2023) 194 https://doi.org/10.18063/ijb.758