Page 401 - IJB-9-5

P. 401

International Journal of Bioprinting A sturgeon cartilage extracellular matrix-derived bioactive bioink

1

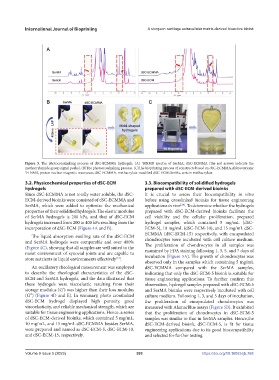

Figure 3. The photocrosslinking process of dSC-ECMMA hydrogels. (A) HNMR spectra of SerMA, dSC-ECMMA (the red arrows indicate the

methacrylamide group signal peaks). (B)The photocrosslinking process. (C)The bioprinting process of constructs based on dSC-ECMMA.Abbreviations:

1 H NMR, proton nuclear magnetic resonance; dSC-ECMMA, methacrylate-modified dSC-ECM; SerMa, sericin methacrylate.

3.2. Physicochemical properties of dSC-ECM 3.3. Biocompatibility of solidified hydrogels

hydrogels prepared with dSC-ECM-derived bioinks

Since dSC-ECMMA is not totally water soluble, the dSC- It is crucial to assess their biocompatibility in vitro

ECM-derived bioinks were consisted of dSC-ECMMA and before using crosslinked bioinks for tissue engineering

SerMA, which were added to optimize the mechanical applications in vivo . To determine whether the hydrogels

[24]

properties of their solidified hydrogels. The elastic modulus prepared with dSC-ECM-derived bioinks facilitate the

of SerMA hydrogels is 200 kPa, and that of dSC-ECM cell viability and the cellular proliferation, prepared

hydrogels increased from 200 to 400 kPa resulting from the hydrogel samples, which contained 5 mg/mL (dSC-

incorporation of dSC-ECM (Figure 4A and B). ECM-5), 10 mg/mL (dSC-ECM-10), and 15 mg/mL dSC-

ECMMA (dSC-ECM-15) respectively, with encapsulated

The liquid absorption swelling rate of the dSC-ECM

and SerMA hydrogels were comparable and over 400% chondrocytes were incubated with cell culture medium.

The proliferation of chondrocytes in all samples was

(Figure 4C), showing that all samples are well suited to the examined by FDA staining following 1, 3, 5, and 7 days of

moist environment of synovial joints and are capable to incubation (Figure 5A). The growth of chondrocytes was

[24]

store nutrients in liquid environments effectively .

observed only in the samples which containing 5 mg/mL

An oscillatory rheological measurement was employed dSC-ECMMA compared with the SerMA samples,

to describe the rheological characteristics of the dSC- indicating that only the dSC-ECM-5 bioink is suitable for

ECM and SerMA hydrogels, and the data illustrated that tissue engineering applications. To further confirm this

these hydrogels were viscoelastic resulting from their observation, hydrogel samples prepared with dSC-ECM-5

storage modulus (G′) was higher than their loss modulus and SerMA bioinks were respectively incubated with cell

(G″) (Figure 4D and E). In summary, photo crosslinked culture medium. Following 1, 3, and 5 days of incubation,

dSC-ECM hydrogel displayed high porosity, good the proliferation of encapsulated chondrocytes was

viscoelasticity, and reliable mechanical strength, which are measured with AlamarBlue assays (Figure 5B). It exhibited

suitable for tissue engineering applications. Hence, a series that the proliferation of chondrocytes in dSC-ECM-5

of dSC-ECM-derived bioinks, which contained 5 mg/mL, samples was similar to that in SerMA samples. Hence,the

10 mg/mL, and 15 mg/mL dSC-ECMMA besides SerMA, dSC-ECM-derived bioink, dSC-ECM-5, is fit for tissue

were prepared and named as dSC-ECM-5, dSC-ECM-10, engineering applications due to its good biocompatibility

and dSC-ECM-15, respectively. and selected for further testing.

Volume 9 Issue 5 (2023) 393 https://doi.org/10.18063/ijb.768