Page 148 - IJB-9-6

P. 148

International Journal of Bioprinting 3D printed bioactive dressings for burn wound treatment

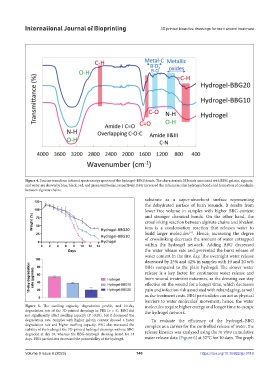

Figure 4. Fourier-transform infrared spectroscopy spectra of the hydrogel–BBG blends. The characteristic IR bands associated with BBG, gelatin, alginate,

and water are shown by blue, black, red, and green text/boxes, respectively. BBG increased the intramolecular hydrogen bonds and formation of crosslinks

between alginate chains.

substrate as a super-absorbent surface representing

the dehydrated surface of burn wounds. It results from

lower free volume in samples with higher BBG content

and stronger chemical bonds. On the other hand, the

crosslinking reaction between alginate chains and bivalent

ions is a condensation reaction that releases water to

build larger molecules . Hence, increasing the degree

[77]

of crosslinking decreases the amount of water entrapped

within the hydrogel network. Adding BBG decreased

the water release rate and prevented the burst release of

water content in the first day. The overnight water release

decreased by 25% and 42% in samples with 10 and 20 w%

BBG compared to the plain hydrogel. The slower water

release is a key factor for continuous water release and

burn wound treatment outcomes, as the dressing can stay

effective on the wound for a longer time, which decreases

pain and infection risk associated with rebandaging, as well

as the treatment costs. BBG particulates can act as physical

barriers to water molecules’ movement; hence, the water

Figure 5. The swelling capacity, degradation profile, and 10-day molecules require higher energy and longer time to escape

degradation rate of the 3D-printed dressings in PBS (n = 5). BBG did the hydrogel network.

not significantly affect swelling capacity (P >0.05), but it decreased the

degradation rate. Samples with higher gelatin content showed a faster To evaluate the efficiency of the hydrogel–BBG

degradation rate and higher swelling capacity. BBG also increased the complex as a carrier for the controlled release of water, the

stability of the hydrogel: the 3D-printed hydrogel dressings without BBG release kinetics was analyzed using the in vitro cumulative

degraded at day 10, whereas the BBG–hydrogel dressing lasted for 14

days. BBG particulates decreased the permeability of the hydrogel. water release data (Figure 6) at 32°C for 10 days. The graph

Volume 9 Issue 6 (2023) 140 https://doi.org/10.36922/ijb.0118