Page 180 - IJB-9-6

P. 180

International Journal of Bioprinting 3D-printed assembly anatomical patella fracture bone plate

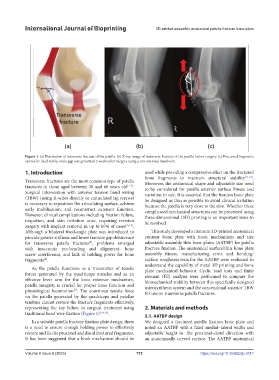

Figure 1. (a) Illustration of transverse fracture of the patella. (b) X-ray image of transverse fracture of the patella before surgery. (c) Fractured fragments

cannot be fixed stably, and a gap was generated 2 weeks after surgery using a conventional band wire.

1. Introduction used while providing a compressive effect on the fractured

bone fragments to maintain structural stability [11,12] .

Transverse fractures are the most common type of patella Moreover, the anatomical shape and adjustable size need

fractures in those aged between 30 and 60 years old [1-5] . to be considered for patella anterior surface fitness and

Surgical intervention with anterior tension band wiring variation in size. It is essential that the fixation bone plate

(TBW) (using K-wires directly or cannulated lag screws) be designed as thin as possible to avoid clinical irritation

is necessary to reposition the articulating surface, achieve because the patella is very close to the skin. Whether these

early mobilization, and reconstruct extensor function. complicated mechanical structures can be processed using

However, clinical complications including fixation failure, three-dimensional (3D) printing is an important issue to

migration, and skin irritation arise, requiring revision be resolved.

surgery with implant removal in up to 65% of cases [4,6-8] .

Although a bilateral fixed-angle plate was introduced to This study developed a titanium 3D-printed anatomical

provide greater stiffness and lower fracture gap dehiscence contour bone plate with hook mechanisms and size

for transverse patella fractures , problems emerged adjustable assembly thin bone plates (AATBP) for patella

[3]

with inaccurate pre-bending and alignment, bone fracture fixation. The anatomical surface/thin bone plate

screw interference, and lack of holding power for bone assembly fitness, manufacturing error, and bending/

fragments . surface roughness tests for the AATBP were evaluated to

[4]

understand the capability of metal 3D printing and bone

As the patella functions as a transmitter of tensile

forces generated by the quadriceps muscles and as an plate mechanical behavior. Cyclic load tests and finite

element (FE) analysis were performed to compare the

effective lever arm for the knee extensor mechanism, biomechanical stability between this specifically designed

patella integrity is crucial for proper knee function and osteosynthesis system and the conventional anterior TBW

physiological locomotion . The enormous tensile force for use on transverse patella fractures.

[9]

on the patella generated by the quadriceps and patellar

tendons cannot restore the fracture fragments effectively,

representing the key failure in surgical treatment using 2. Materials and methods

traditional band wire fixation (Figure 1) [3,4,10] .

2.1. AATBP design

In a suitable patella fracture fixation plate design, there We designed a fractured patella fixation bone plate and

is a need to ensure enough holding power to effectively noted an AATBP with a fixed medial–lateral width and

restore and fix the proximal and distal fractured fragments. adjustable height in the proximal–distal direction with

It has been suggested that a hook mechanism should be an anatomically curved surface. The AATBP anatomical

Volume 9 Issue 6 (2023) 172 https://doi.org/10.36922/ijb.0117