Page 190 - IJB-9-6

P. 190

International Journal of Bioprinting 3D-printed assembly anatomical patella fracture bone plate

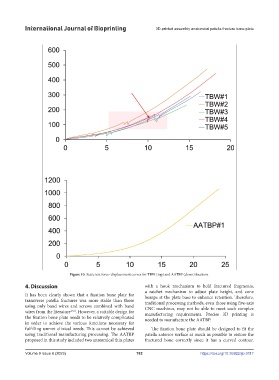

Figure 10. Static test force–displacement curves for TBW (top) and AATBP (down) fixations.

4. Discussion with a hook mechanism to hold fractured fragments,

a ratchet mechanism to adjust plate height, and cone

It has been clearly shown that a fixation bone plate for bumps at the plate base to enhance retention. Therefore,

transverse patella fractures was more stable than those traditional processing methods, even those using five-axis

using only band wires and screws combined with band CNC machines, may not be able to meet such complex

wires from the literature [3,4] . However, a suitable design for manufacturing requirements. Precise 3D printing is

the fixation bone plate needs to be relatively complicated needed to manufacture the AATBP.

in order to achieve the various functions necessary for

fulfilling unmet clinical needs. This cannot be achieved The fixation bone plate should be designed to fit the

using traditional manufacturing processing. The AATBP patella anterior surface as much as possible to restore the

proposed in this study included two anatomical thin plates fractured bone correctly since it has a curved contour.

Volume 9 Issue 6 (2023) 182 https://doi.org/10.36922/ijb.0117