Page 186 - IJB-9-6

P. 186

International Journal of Bioprinting 3D-printed assembly anatomical patella fracture bone plate

Table 2. Surface roughness measured positions for the AATBP and corresponding obtained results

Sample 1 4.135 5.960 5.454 3.323

Sample 2 4.427 5.495 4.438 3.545

Sample 3 4.698 5.325 6.264 3.824

Mean ± Std (µm) 4.42 ± 0.28 5.59 ± 0.33 5.39 ± 0.91 3.56 ± 0.25

Unit: µm

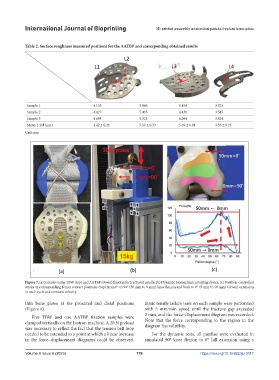

Figure 7. (a) Samples using TBW (top) and AATBP (down) fixation for fractured patella. (b) Dynamic biomechanical testing device. (c) Position-controlled

stroke of corresponding femur contact positions (top) from 0° to 90° (50 mm to 0 mm) knee flexion and back to 0° (0 mm to 50 mm) (down) extension

in each cycle at a constant velocity.

thin bone plates at the proximal and distal positions Static tensile failure tests on each sample were performed

(Figure 8). with 5 mm/min speed until the fracture gap exceeded

Five TBW and one AATBP fixation samples were 2 mm, and the force–displacement diagram was recorded.

clamped vertically on the Instron machine. A 20 N preload Note that the force corresponding to the region in the

was necessary to reflect the fact that the tension belt loop diagram has volatility.

needed to be extended to a point at which a linear increase For the dynamic tests, all patellae were evaluated in

in the force–displacement diagrams could be observed. simulated 90° knee flexion to 0° full extension using a

Volume 9 Issue 6 (2023) 178 https://doi.org/10.36922/ijb.0117