Page 20 - IJB-4-1

P. 20

Progress in organ 3D bioprinting

advantages and disadvantages in bioartificial organ The advantages of inkjet-based bioprinting in organ

manufacturing areas [9–11] . An obvious advantage of the 3D bioprinting contain the fast response speed, the high

MNRP technology is that it can produce bioartificial organs formation precision, and the high efficiency. These can be

automatically mimicking their natural counterparts using analysed through two aspects. On the one hand, the acoustic

heterogeneous cell types and other biomaterials. In this 3D bioprinters can be well-controlled through adjusting

article, we highlight some of the three-dimensional (3D) the jetting direction, droplet size, and cell viability. On the

achievements of various bioprinting technologies in five other hand, the thermal bioprinters can be well-controlled

large organs, including the bone, liver, heart, cartilage and through adjusting the printing speed and cost. One obvious

skin, manufacturing. drawback of inkjet bioprinting in organ 3D bioprinting

2.Different Types of Bioprinting is that the “bioinks” should be in liquid forms with low

[13]

viscosities . This has greatly limited the height of the

Given that working principles, five major types of 3D constructs. Only low concentration of polymeric bioinks

6

bioprinting technologies include inkjet-based bioprinting, with a low cell density (fewer than 10 cells/mL) can avoid

extrusion-based bioprinting, laser-assisted bioprinting, nozzle clogging and reduce shear stress on cells [15–17] .

stereolithography-based bioprinting and microvalve-based Another obvious drawback of inkjet bioprinting in organ

bioprinting [12–14] . Among these technologies extrusion-based 3D bioprinting is the poor mechanical properties of the 3D

bioprinting technologies have been widely used to build constructs. Till now, most of the researchers in this field

cell-laden 3D tissues and organs. do their studies by modifying commercial inkjet printing

2.1 Inkjet-based Bioprinting systems to print living cells. This has greatly limited their

development in soft and hardware as well as the complexity

of printed constructs. Due to these drawbacks, inkjet-based

bioprinting is still in its infancy stage for large organ 3D

(A) (B)

bioprinting whereas extrusion-based bioprinting has been

prevalently used for numerous studies.

2.2 Extrusion-based Bioprinting

(A) (B)

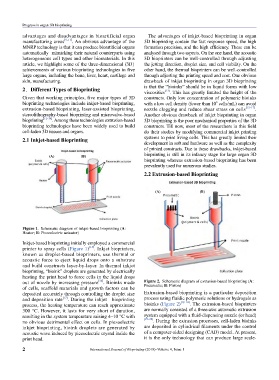

Figure 1. Schematic diagram of inkjet-based bioprinting (A:

Heater; B: Piezoelectric actuator)

Inkjet-based bioprinting initially employed a commercial

printer to spray cells (Figure 1) [15] . Inkjet bioprinters,

known as droplet-based bioprinters, use thermal or

acoustic force to eject liquid drops onto a substrate

and build constructs layer-by-layer. In thermal inkjet

bioprinting, “bioink” droplets are generated by electrically

heating the print head to force cells in the liquid drops

out of nozzle by increasing pressure [16] . Bioinks made Figure 2. Schematic diagram of extrusion-based bioprinting (A:

Pneumatic; B: Piston)

of cells, scaffold materials and growth factors can be

deposited accurately through controlling the droplet size Extrusion-based bioprinting is a particular deposition

and deposition rate [17] . During the inkjet bioprinting process using fluidic polymeric solutions or hydrogels as

[18–24]

process, the heating temperature can reach approximate bioinks (Figure 2) . The extrusion-based bioprinters

300 °C. However, it lasts for very short of duration, are normally consisted of a three-axis automatic extrusion

resulting in the system temperature raising 4–10 °C with system equipped with a fluid-dispensing nozzle (or head)

[25–28]

no obvious detrimental effect on cells. In piezoelectric . During the extrusion processes, cell-laden bioinks

inkjet bioprinting, bioink droplets are generated by are deposited in cylindrical filaments under the control

acoustic wave induced by piezoelectric crystal inside the of a computer-aided designing (CAD) model. At present,

print head. it is the only technology that can produce large scale-

2 International Journal of Bioprinting (2018)–Volume 4, Issue 1