Page 198 - IJB-9-2

P. 198

International Journal of Bioprinting A regulated GelMA-MSCs scaffold by three-dimensional bioprinting

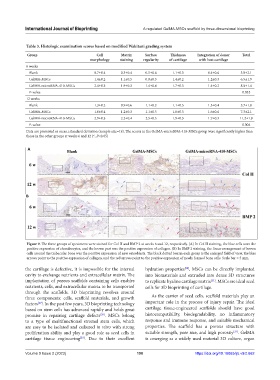

Table 3. Histologic examination scores based on modified Wakitani grading system

Group Cell Matrix Surface Thickness Integration of donor Total

morphology staining regularity of cartilage with host cartilage

6 weeks

Blank 0.7±0.4 0.3±0.4 0.5±0.6 1.1±0.3 0.4±0.6 3.0±2.1

GelMA-MSCs 1.4±0.2 1.1±0.5 0.9±0.3 1.4±0.2 1.2±0.3 6.5±1.9

GelMA-microRNA-410-MSCs 2.4±0.3 1.9±0.3 1.4±0.4 1.7±0.5 1.4±0.2 8.8±1.4

P-value 0.032

12 weeks

Blank 1.3±0.2 0.9±0.6 1.1±0.2 1.1±0.5 1.3±0.4 5.7±1.8

GelMA-MSCs 1.6±0.4 1.2±0.3 1.1±0.5 1.8±0.5 1.6±0.6 7.3±2.1

GelMA-microRNA-410-MSCs 2.9±0.3 2.2±0.4 2.5±0.5 1.9±0.3 1.7±0.3 11.2±1.9

P-value 0.004

Data are presented as mean±standard deviation (sample size=18). The scores in the GelMA-microRNA-410-MSCs group were significantly higher than

those in the other groups at weeks 6 and 12 (*, P<0.05)

A

B

Figure 9. The three groups of specimens were stained for Col II and BMP 2 at weeks 6 and 12, respectively. (A) In Col II staining, the blue cells were the

positive expression of chondrocytes, and the brown part was the positive expression of collagen. (B) In BMP 2 staining, the linear arrangement of brown

cells around the trabecular bone was the positive expression of new osteoblasts. The black dotted box in each group is the enlarged field of view, the blue

arrows point to the positive expression of collagen, and the red arrows point to the positive expression of newly formed bone cells. Scale bar = 5 mm.

the cartilage is defective, it is impossible for the internal hydration properties , MSCs can be directly implanted

[30]

cavity to exchange nutrients and extracellular matrix. The into biomaterials and extruded into dense 3D structures

implantation of porous scaffolds containing cells enables to replicate hyaline cartilage matrix . MSCs are ideal seed

[31]

nutrients, cells, and extracellular matrix to be transported cells for 3D bioprinting of cartilage.

through the scaffolds. 3D bioprinting revolves around

three components: cells, scaffold materials, and growth As the carrier of seed cells, scaffold materials play an

factors . In the past few years, 3D bioprinting technology important role in the process of injury repair. The ideal

[27]

based on stem cells has advanced rapidly and holds great cartilage tissue-engineered scaffolds should have good

[28]

promise in repairing cartilage defects . MSCs belong histocompatibility, biodegradability, no inflammatory

to a type of multifunctional stromal stem cells, which response and immune response, and suitable mechanical

are easy to be isolated and cultured in vitro with strong properties. The scaffold has a porous structure with

proliferation ability and play a good role as seed cells in suitable strength, pore size, and high porosity . GelMA

[32]

cartilage tissue engineering . Due to their excellent is emerging as a widely used material 3D culture, organ

[29]

Volume 9 Issue 2 (2023) 190 https://doi.org/10.18063/ijb.v9i2.662